Door And Window Profiles

|

|

What Are Advantages of Aluminum Profile For Door And Window

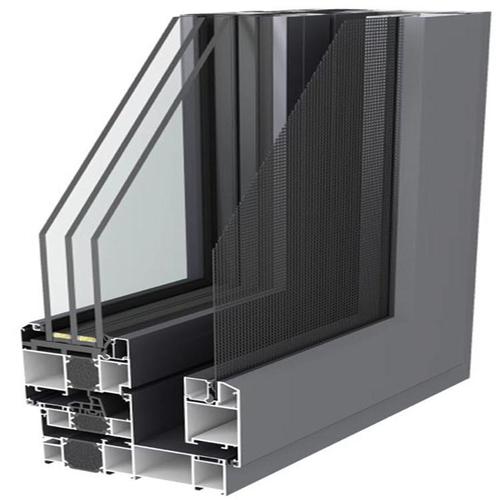

Aluminum profiles have good wind pressure resistance, air tightness and sound insulation, and a good door and window system needs to have such characteristics. Compared with stainless steel and uPVC, aluminum profiles have the highest cost performance.1. Aluminum profiles can be customized according to different needs and have various appearance design options. It can meet the requirements of various architectural styles, colors and shapes, matching the door and window system with the overall architectural style, and improving the aesthetics and personalization of the building.

2. Aluminum profiles are resistant to acid and alkali erosion, are not corroded by acid rain and ozone, are resistant to ultraviolet rays, and maintain their inherent color and luster for a long time.

3. Aluminum profiles for doors and windows are metal materials. Aluminum plus various metal elements are made into various alloys. They have unparalleled advantages of other door and window materials. They are light in weight and high in strength. They can be extruded into various composite cross-section profiles used in various periods. , which can meet various new cross-section requirements of door and window designers.

4. Aluminum alloy doors and windows have various surface treatment technologies, such as powder spraying, anodizing, electrophoretic coating, and wood grain transfer treatment. They are available in a variety of colors and wood grains. The options are rich and can meet the needs of various architectural decorations.

|

Name |

Aluminum window and door profiles |

|

Material |

6000 series |

|

Temper |

T3-T8 |

|

Surface Treatment |

Mill-Finished, Anodizing, Powder Coating, PVDF, Electrophoresis, Wood Grain, Polishing, Brushing, etc |

|

Colour |

Silver, champagne, Bronze, Golden, Black, White, Gray, Sand coating, Anodized Acid, Alkali, and wood texture, or Customized |

|

Length |

3.0-7.2 Meters or Customized |

|

Thickness |

0.4mm-20mm or Customized |

|

Film Standard |

Anodized:7-23 μ , Powder coating: 60-80 μ , Electrophoresis film: 12-25 μ |

|

Profile type |

1. Sliding window and door profiles |

|

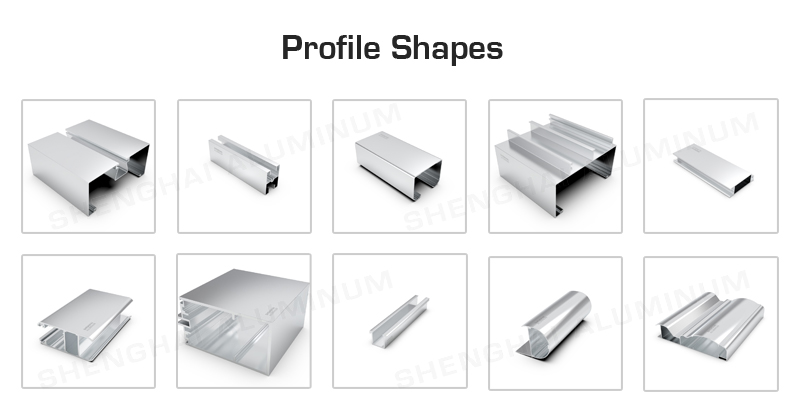

Shape |

Square, angled, flat, hollow, oval, triangle, U-profile, L-profile, T-profiles, H-profiles, or customized available |

|

Free Samples |

About 3 workdays can be sent |

|

Deep Processing |

CNC / Precise cutting / Punching / Checking / Tapping / Drilling / Milling / Fabricating |

|

Certification |

1. ISO9001-2008 |

|

Design |

OEM or ODM is available, please send us your drawing |

|

Packaging Details |

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box |

What are the shapes of aluminum profiles for doors and windows?

There are many aluminum profiles in many shapes for doors and windows. Choose the appropriate profile shape according to different design and functional requirements. Common shapes of door and window aluminum profiles include: square (mainly used for door and window frames), round (used for round or curved door and window structures), oval, angle aluminum (L, T-shaped, mainly used for connecting profiles), Special shapes (U-shaped, C-shaped), etc. Different designs will have different profiles used for doors and windows. Generally speaking, professional door and window profile manufacturers have sufficient capabilities to produce the door and window profiles that customers need.

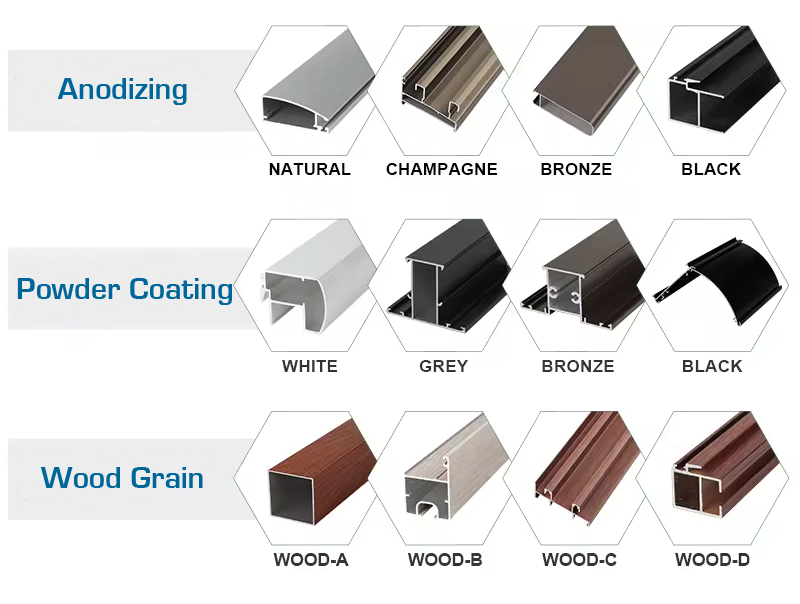

What surface treatments are usually performed on door and window aluminum profiles?

The aesthetics of aluminum doors and windows are inseparable from their surface treatment process. Good surface treatment can enhance the corrosion and weather resistance of doors and windows, extending their service life. Various color customizations and ever-changing architectural styles make it appear more modern, fashionable, simple, and personalized, catering to consumers' pursuits. So, what are the common surface treatments for door and window profiles?Anodizing

Anodizing treatment refers to covering an oxide film on the surface of aluminum alloy profiles through the action of electric current under the corresponding electrolytic solution and specific process. Anodized aluminum profiles overcome the disadvantage of easy wear to a certain extent; oxidized aluminum profiles with stronger metallic texture are high-end and beautiful, have uniform colors and are not easy to fade.

Powder coating

Powder coating uses electrostatic spraying equipment to spray powder coating onto the surface of the profile; under static electricity, the powder will be evenly adsorbed on the surface of the profile to form a powdery coating. The powdery coating is then baked, leveled, and solidified at high temperatures to become a final coating with different effects. Powder-coated aluminum profiles are available in various colors, have a low probability of color difference, and have good corrosion resistance.

Fluorocarbon spraying

Fluorocarbon spraying and powder spraying both belong to electrostatic spraying. The difference lies in the liquid spray used in fluorocarbon spraying. The advantage of fluorocarbon spraying is that the aluminum profile coating is smooth, non-dazzling, and has stronger weather resistance; it can show stronger corrosion resistance in unfavorable climate environments and coastal areas.

Wood grain

Wood grain transfer is based on powder spraying or electrophoretic coating, based on the principle of high-temperature sublimation thermal penetration; through heating and pressure, the wood grain texture pattern on the transfer paper or transfer film is quickly transferred and penetrated the already existing Spray or electrophoresis the profile. Common colors are Oak, Walnut, Cherry, Maple, Mahogany, etc.

The clear and natural wood grain color satisfies many consumers' pursuit of natural and peaceful life and has been widely used in the aluminum alloy doors and windows market. The advantage of wood grain transfer is that it is resistant to aging, fading, corrosion and weathering. The wood grain texture with a better three-dimensional effect is also an ideal choice to replace traditional wood.

As customization of doors and windows becomes increasingly popular, more and more consumers have higher requirements for personalized doors and windows, and the color of doors and windows is one of them. More color customization can provide more choices for interior decoration styles, and properly coordinated door and window colors can add a lot of color to the entire home effect.

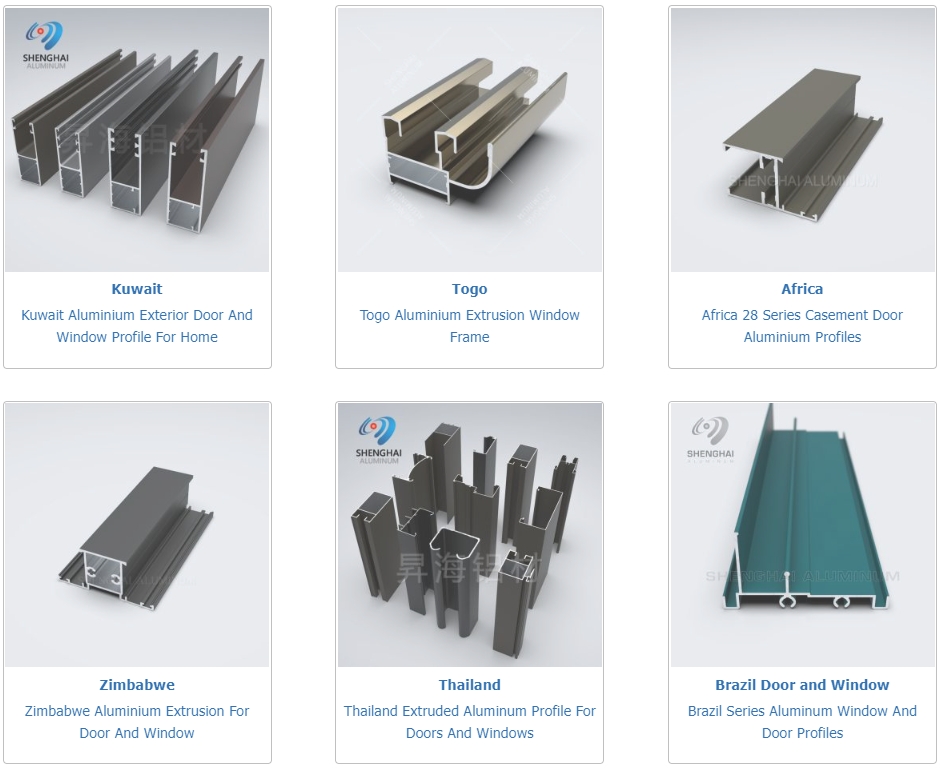

Which door and window systems are our aluminum profiles suitable for?

Shenghai Aluminum is a professional aluminum profile extrusion manufacturer. Our door and window system profiles are rich and suitable for various types of doors and windows. Standard ones include casement doors and windows, sliding doors and windows, folding doors and windows, turn and tilt, swing, thermal break doors and windows, etc. In addition to standard door and window systems, there are also some door and window profiles for special requirements. If you want to know more about door and window profiles, you can contact us and get profile information for free.

What customized services do we support?

Shenghai Aluminum is a China-based manufacturer that integrates aluminum extrusion and deep processing. It has professional drawing design, mold production, extrusion and other engineering teams. The aluminum profiles we provide to our customers are either standard or customized. So, what customized services can we provide?1.Surface treatment

We can adopt the surface treatment methods customers require according to their needs. (Brushing, polishing, sandblasting, anodizing, powder coating, fluorocarbon spraying, electrophoresis, etc.)

2. Machining

We support high-precision cutting, CNC machining, drilling, bending, mechanical polishing, etc.

3. Aluminum alloy grade selection

In addition to some commonly used 6061, 6063 grade aluminum alloys, we can also provide 6060, 6005, 6082 etc.