Aluminum Trim Edge

|

|

About Extruded Aluminum Trim Edge Strip

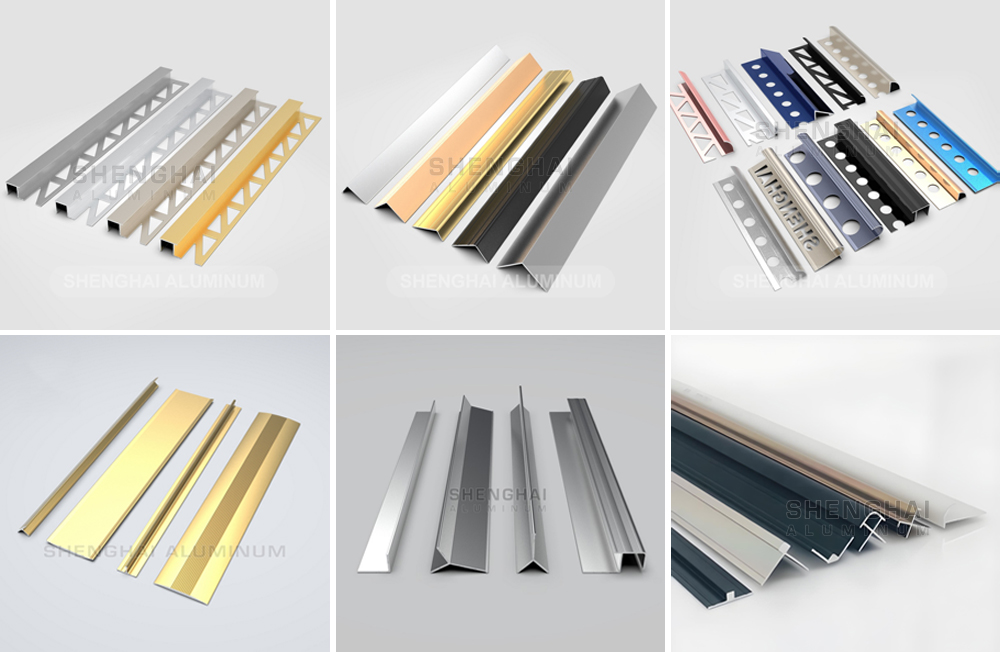

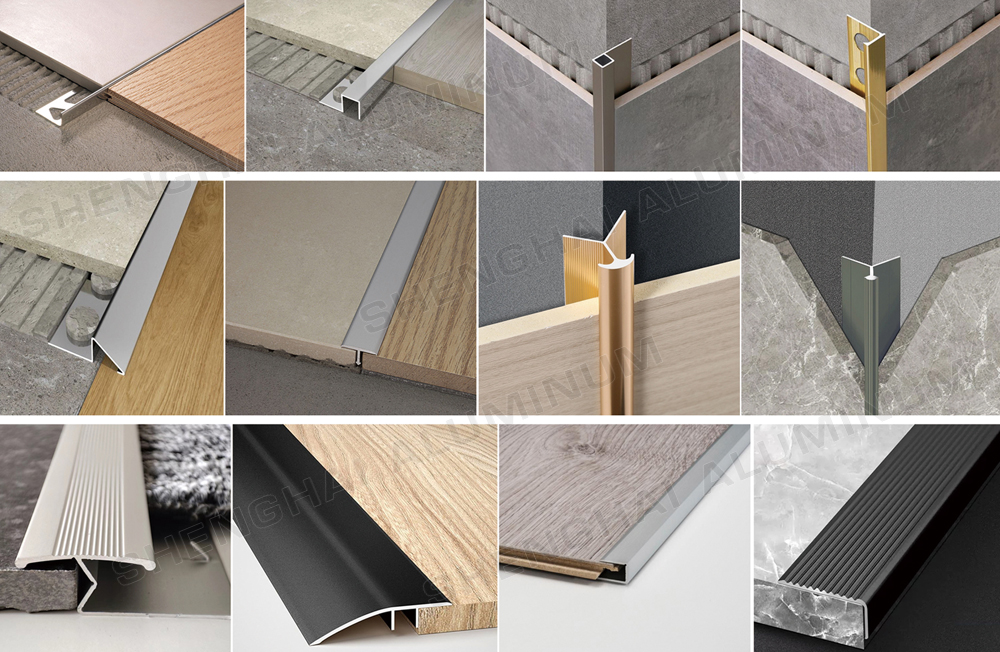

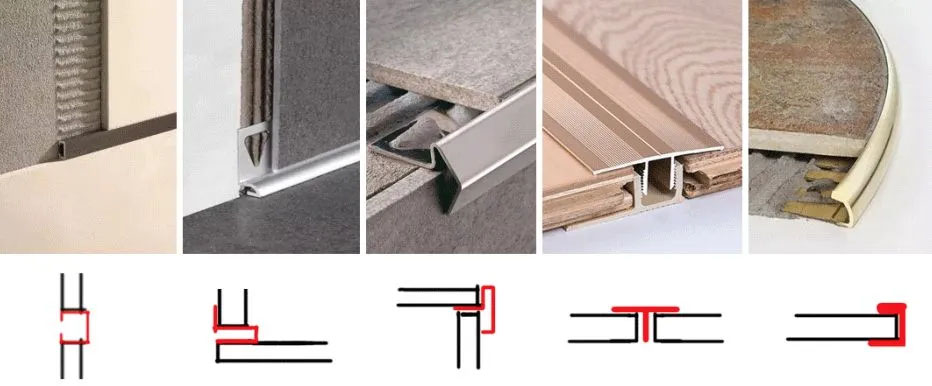

Extruded aluminum edge strips have trimming and decorative functions, which can enhance the aesthetics of various applications and protect walls, tiles, floors, etc. Aluminum trim edge strips mainly include U-shaped strips, T-shaped strips, decorative strips, aluminum skirting strips, etc., and can be customized.Types of Extruded Aluminum Trim Edge Strip

Commonly used trim edge shapes are round shape trim, corner edge, T shape edging trim, L shaped tile trim, etc.Extruded Aluminum Trim Edge Strip Application

Aluminum trim for tiles, Aluminum floor transition strip, Aluminium carpet edge, Aluminium listello trim, Aluminum stair trim, etc.

|

Product Name |

Extruded Aluminum Trim Edge Strip |

|

Material |

6063 or 6061 Aluminum Alloy |

|

Temper |

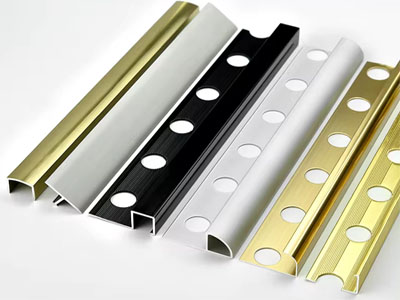

Shape:Round/Square/L/U/Customized. |

|

Specification |

Color:Silver/Gold/Champagne/Bronze/Black/White/Customized |

|

Surface Treatment:Mill finish/Polishing/Anodized/Coating/Customized |

|

|

Length:0.9/1.0/2.4/2.5/2.6/2.7/2.8/3.0/ Customized |

|

|

Thickness:0.5-1.5mm/Customized |

|

|

Application |

Tiles/Wood Floor/Stairs/Carpet/Transition, etc. |

|

Punching Hold |

Round/Trapezoid/Triangle/Regular Triangle/Square/Customized |

|

Service |

1. Free sample, Free design;

2. OEM/ODM available;

3. Custom-made request;

4. New design solution suggestion

|

|

Packaging |

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box |

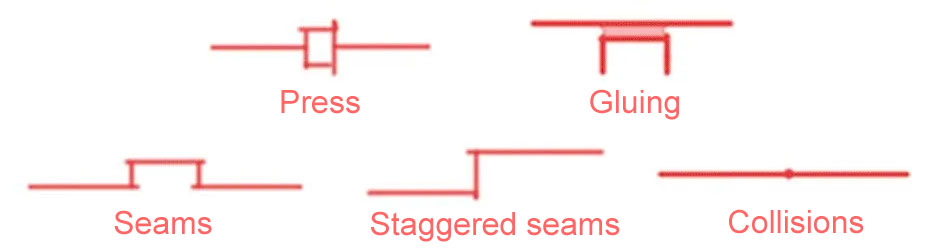

What Are the Installation Methods for Aluminum Trim Edge Strips?

What are the main methods of trimming aluminum edge strips? In fact, all interior decoration edge strips can be summarized into five situations: pressing, gluing, leaving seams, staggered seams, and collisions.

How To Extrude Aluminum Trim Edge Strip

The core link of aluminum profile extrusion is the extrusion process, which includes profile heating, extrusion die, extrusion molding and other steps.Heated aluminum round rod

First, heat the aluminum rod to the appropriate processing temperature. We generally use resistance furnace heating.

Mold

The mold is designed according to the shape and size of the edge strip required by the customer, and the profile of aluminium needed is extruded through the mold.

Extrusion molding

The heated aluminum round bar material is placed into the extrusion cylinder, and the aluminum round bar is extruded by injecting high-pressure liquid into the extrusion cylinder or using a mechanical pressure device to cause plastic deformation and ejection from the die hole of the extrusion die. Extrusion to complete the extrusion molding process of aluminum profiles.