Best Aluminum Window Profiles for Energy Efficiency

Updated: 20 Jan 2026

Nowadays, the combination of energy conservation and architecture has become an important direction of modern development. Aluminum window profiles have emerged as the preferred choice for engineers and property owners due to their corrosion resistance, stable structure and low maintenance requirements. Compared to wood, which is prone to deformation and steel, which is prone to rust, aluminum alloy can effectively reduce heat loss and cold air infiltration, achieving long-term energy conservation. Its excellent sealing performance and diverse designs make it widely used in residential, office buildings and commercial projects, and it is an ideal solution for energy efficiency aluminum window profiles.

Energy efficiency aluminum windows are a comprehensive reflection of the heat transfer coefficient, sound insulation and air tightness, as well as the production process. Window profiles are especially important for energy-saving aluminum windows.

Thermal Conductivity Coefficients (R value and U-value)

To evaluate the energy efficiency performance of a window frame, the core indicators are the R-value and U-value. These values directly reflect the window's insulation performance and are crucial for choosing the best window materials. These two values account for all components of the window, including glass, the window frame, and a low-emissivity coating.

U-value: Measures the ability of a window to prevent non-sunlight heat from escaping or being absorbed. The lower the U-value, the more difficult it is for heat to pass through the window, indicating better insulation and heat preservation performance.

R-value: Measures the insulation performance of a material itself, influenced by factors such as thickness and material type. The higher the R-value, the better the insulation effect.

In simple terms, the lower the U-value and the higher the R-value, the better the window's insulation and heat retention will be, achieving true energy-saving effects.

Sound Insulation and Air Tightness

High-performance, energy-saving aluminum window profiles not only focus on heat insulation and preservation but also excel in sound insulation and air tightness. The high-quality aluminum profile structure is stable, combined with a multi-chamber design and sealing rubber strips, effectively blocking outdoor noise and enhancing indoor comfort. At the same time, the tight, air-tight design ensures that the windows have almost no air leakage when closed, reducing the entry of cold or hot air into the room and thereby reducing energy consumption at the source. Whether in busy urban areas or in hot or cold environments, energy-saving aluminum window profiles can provide a quiet, comfortable, and energy-efficient living and working space.

Production Process

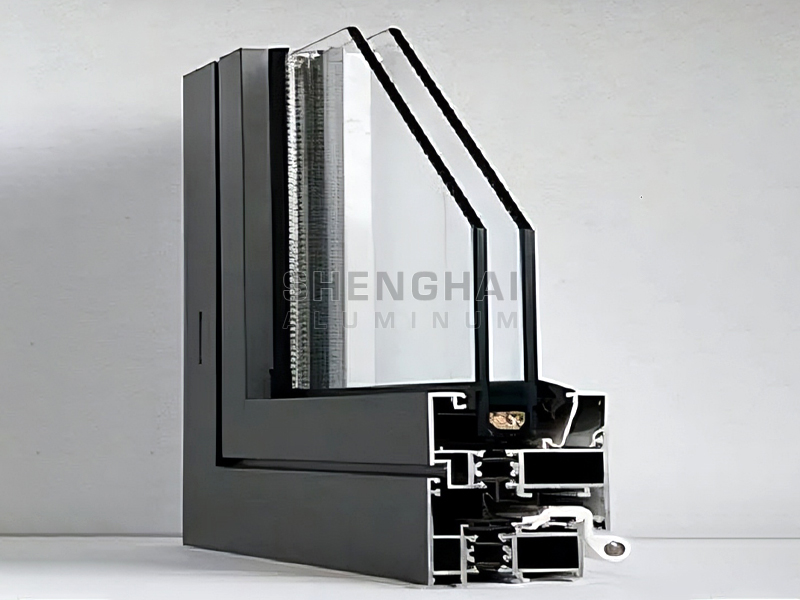

The performance of energy-saving architecture aluminum window profiles is determined from the very beginning by the materials and manufacturing processes. Firstly, the material thickness, extrusion process, and structural design are the key factors. A reasonable aluminum thickness ensures the profiles' strength; advanced extrusion processes precisely control the profiles' cross-sectional shape; and a multi-chamber structural design not only enhances the profiles' load-bearing and stability but also effectively improves insulation and air tightness, thereby achieving the maximum energy-saving effect.

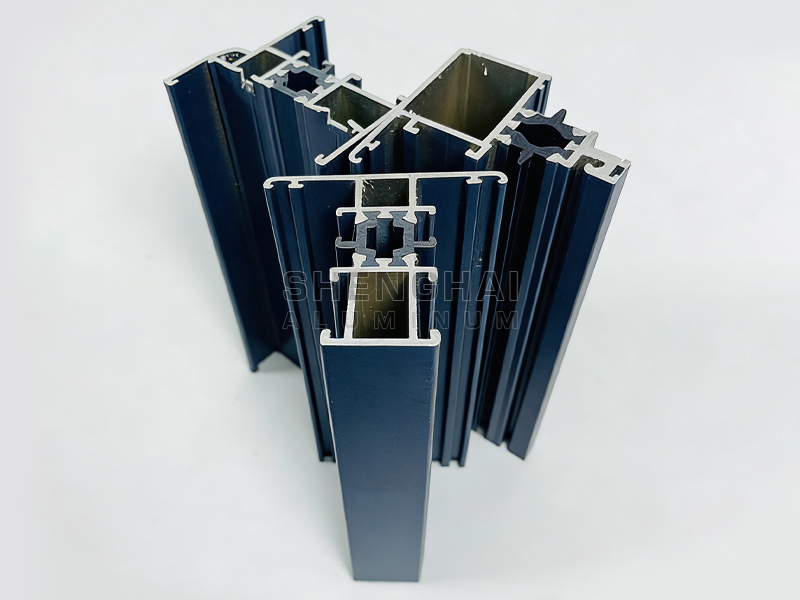

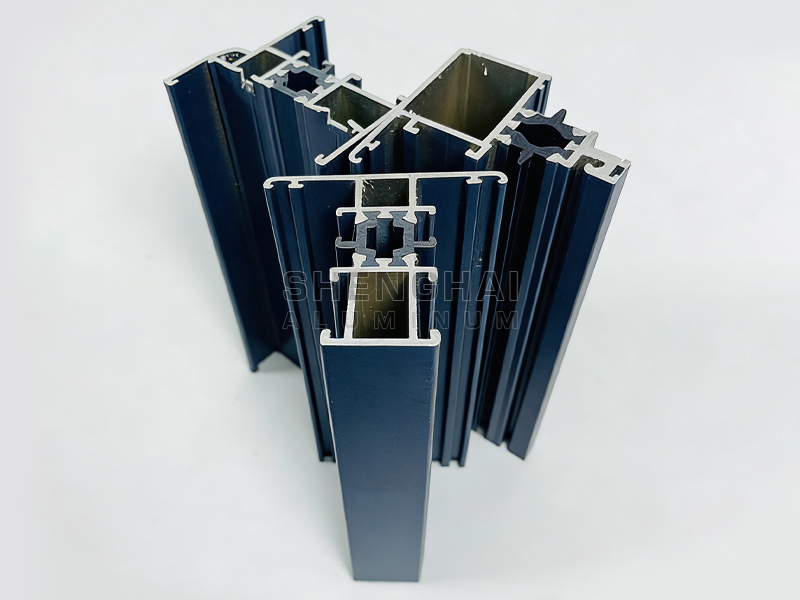

Secondly, the surface treatment process is equally crucial for the durability and appearance of the profiles. Anodizing treatment can form a dense oxide film, enhancing corrosion resistance and scratch resistance; powder coating not only offers a wide range of color options for the profiles but also strengthens their resistance to ultraviolet rays and weathering, ensuring that the window profiles remain aesthetically pleasing and in good condition over a long period of use.

By selecting scientific materials and employing meticulous processing techniques, the energy-efficient aluminum window profiles achieve a perfect balance between performance and aesthetics, meeting the long-term use requirements of high-end residences and commercial projects.

Its high strength and durability are the key to ensuring long-term usage effectiveness. The high-quality aluminum alloy material is sturdy and durable, and is not prone to deformation or cracking. Even after long-term use or in extreme climatic conditions, the window type can still maintain stable performance and provide reliable structural support for the building.

Architectural aluminum window profiles have excellent sealing performance. Through the multi-chamber design and high-precision processing, combined with high-quality sealing strips, it effectively reduces heat loss and cold air infiltration, making indoor temperatures more stable and significantly improving the energy efficiency of air conditioning and heating systems. The excellent air tightness not only reduces energy consumption but also enhances the comfort of living and working environments.

Aluminum alloy has excellent anti-corrosion and rust resistance properties. Even when exposed to moisture or salt spray for a long time, it is not easily affected by corrosion. Combined with surface treatment processes such as anodizing or powder coating, the window type is not only aesthetically pleasing and durable, but also significantly reduces maintenance costs, enabling long-term, reliable use.

Overall, the aluminum window profiles offer comprehensive advantages in energy conservation, durability, and low maintenance through their sturdy, durable structure, excellent sealing performance, and outstanding weather resistance. They are the ideal choice for high-quality residential, office, and commercial buildings.

Aluminum alloy window profiles: Excellent sealing performance, effectively preventing the convection of hot and cold air. The profiles have high strength and do not deform even after long-term use. The material is recyclable. Corrosion-resistant and with stable performance over a long period.

Wooden window profiles: They have good natural insulation performance but are prone to cracking and deformation in humid environments, are susceptible to moisture, and have a rapid deterioration in sealing performance. The procurement and maintenance costs are high. Regular anti-corrosion, moisture-proofing, and maintenance are required.

PVC window profiles: The procurement cost is low, and the heat insulation and heat preservation performance are excellent. The profiles are lightweight, easy to process, and install. However, they have poor heat resistance. When exposed to high temperatures for a long time, they will age and become brittle, resulting in a decrease in insulation effect. In the later stage, frequent replacement of accessories is required, and the maintenance cost will increase year by year.

Stainless steel window profiles: Extremely strong and highly resistant to impact. However, they have high thermal conductivity, resulting in poor energy efficiency and rapid heat transfer between indoors and outdoors. Non-304/316 stainless steel models are prone to rust, affecting both appearance and sealing performance. The procurement cost is high, the long-term energy-saving loss is significant, and the maintenance cost is relatively high.

A: Aluminum windows are renowned for their excellent insulation properties, which help reduce heat loss and enhance the insulation of the house. They are also durable, have low maintenance costs, and are easy to recycle.

Q: How are aluminium profile windows different from other types of windows in terms of energy efficiency?

A: Aluminium windows, with modern technologies such as insulation breaks and high-performance glass, have outstanding energy-saving performance. Although PVC windows usually have better insulation properties due to their non-conductive nature, when properly configured, high-quality aluminium window systems can achieve, and even surpass, the insulation performance of PVC windows.

Q: Can architectural aluminum windows help me reduce energy costs?

A: Yes, installing aluminum windows can enhance the insulation of the house, reduce heat loss, and thereby help you lower energy expenses. Aluminum windows have excellent insulation properties, helping maintain a comfortable indoor temperature year-round.

Q: Why are aluminium profile windows considered as environmentally friendly and energy-saving materials?

A: Aluminium windows are regarded as environmentally friendly products for two reasons: Firstly, aluminium is a highly sustainable material that can be infinitely recycled without losing its quality. Secondly, they have a long service life of over 20 years, reducing the energy waste from frequent replacements and aligning with the concept of green buildings.

Q: Do high-rise residential aluminum windows have other advantages besides energy saving?

A: High-rise residential buildings have strict requirements for the wind resistance and sealing performance of doors and windows. Aluminum windows are highly durable and less prone to deformation. They can withstand strong winds and also block outdoor noise and hot/cold air. This not only saves energy but also enhances living comfort.

Q: Are you a reliable supplier of architectural aluminum window profiles?

A: Yes, Shenghai Aluminum has over 15 years of experience. We have completed more than 50 window and door profile projects. For more information, please contact us.

Energy Efficient Aluminum Window Profiles - A Worthy Choice

A truly energy-efficient building starts with the insulation and heat retention capabilities of its doors and windows. High-quality, energy-saving aluminum window frames can minimize heat loss, reducing window energy consumption to an optimal level. Compared to traditional windows and doors, their insulation performance can be improved by more than four times, effectively blocking heat exchange. Choosing high-energy-efficient aluminum window frames not only complies with strict building energy-saving standards and enhances project value, but also reduces leakage, deformation, and other issues, lowers maintenance costs after installation, and delivers long-term, reliable energy-saving benefits to both owners and contractors.Energy efficiency aluminum windows are a comprehensive reflection of the heat transfer coefficient, sound insulation and air tightness, as well as the production process. Window profiles are especially important for energy-saving aluminum windows.

Thermal Conductivity Coefficients (R value and U-value)

To evaluate the energy efficiency performance of a window frame, the core indicators are the R-value and U-value. These values directly reflect the window's insulation performance and are crucial for choosing the best window materials. These two values account for all components of the window, including glass, the window frame, and a low-emissivity coating.

U-value: Measures the ability of a window to prevent non-sunlight heat from escaping or being absorbed. The lower the U-value, the more difficult it is for heat to pass through the window, indicating better insulation and heat preservation performance.

R-value: Measures the insulation performance of a material itself, influenced by factors such as thickness and material type. The higher the R-value, the better the insulation effect.

In simple terms, the lower the U-value and the higher the R-value, the better the window's insulation and heat retention will be, achieving true energy-saving effects.

Sound Insulation and Air Tightness

High-performance, energy-saving aluminum window profiles not only focus on heat insulation and preservation but also excel in sound insulation and air tightness. The high-quality aluminum profile structure is stable, combined with a multi-chamber design and sealing rubber strips, effectively blocking outdoor noise and enhancing indoor comfort. At the same time, the tight, air-tight design ensures that the windows have almost no air leakage when closed, reducing the entry of cold or hot air into the room and thereby reducing energy consumption at the source. Whether in busy urban areas or in hot or cold environments, energy-saving aluminum window profiles can provide a quiet, comfortable, and energy-efficient living and working space.

Production Process

The performance of energy-saving architecture aluminum window profiles is determined from the very beginning by the materials and manufacturing processes. Firstly, the material thickness, extrusion process, and structural design are the key factors. A reasonable aluminum thickness ensures the profiles' strength; advanced extrusion processes precisely control the profiles' cross-sectional shape; and a multi-chamber structural design not only enhances the profiles' load-bearing and stability but also effectively improves insulation and air tightness, thereby achieving the maximum energy-saving effect.

Secondly, the surface treatment process is equally crucial for the durability and appearance of the profiles. Anodizing treatment can form a dense oxide film, enhancing corrosion resistance and scratch resistance; powder coating not only offers a wide range of color options for the profiles but also strengthens their resistance to ultraviolet rays and weathering, ensuring that the window profiles remain aesthetically pleasing and in good condition over a long period of use.

By selecting scientific materials and employing meticulous processing techniques, the energy-efficient aluminum window profiles achieve a perfect balance between performance and aesthetics, meeting the long-term use requirements of high-end residences and commercial projects.

The Advantages Of Aluminum Window Profiles In Terms Of Energy Efficiency

Aluminum window profiles, with their outstanding physical properties and refined design, demonstrate significant advantages in energy-efficient buildings. Both in terms of appearance, design and performance, they are highly favored by architectural designers and project managers.Its high strength and durability are the key to ensuring long-term usage effectiveness. The high-quality aluminum alloy material is sturdy and durable, and is not prone to deformation or cracking. Even after long-term use or in extreme climatic conditions, the window type can still maintain stable performance and provide reliable structural support for the building.

Architectural aluminum window profiles have excellent sealing performance. Through the multi-chamber design and high-precision processing, combined with high-quality sealing strips, it effectively reduces heat loss and cold air infiltration, making indoor temperatures more stable and significantly improving the energy efficiency of air conditioning and heating systems. The excellent air tightness not only reduces energy consumption but also enhances the comfort of living and working environments.

Aluminum alloy has excellent anti-corrosion and rust resistance properties. Even when exposed to moisture or salt spray for a long time, it is not easily affected by corrosion. Combined with surface treatment processes such as anodizing or powder coating, the window type is not only aesthetically pleasing and durable, but also significantly reduces maintenance costs, enabling long-term, reliable use.

Overall, the aluminum window profiles offer comprehensive advantages in energy conservation, durability, and low maintenance through their sturdy, durable structure, excellent sealing performance, and outstanding weather resistance. They are the ideal choice for high-quality residential, office, and commercial buildings.

Energy Efficiency Aluminum Window Profiles VS Wood, PVC, and Stainless Steel

When choosing window and door profiles, there are four types of materials: aluminium alloy, wood, PVC, and stainless steel each with its own advantages and disadvantages. The performance differences directly affect the energy-saving effect, operational and maintenance costs, and the building's lifespan. Here is a comparison of the characteristics of these four types of profiles:Aluminum alloy window profiles: Excellent sealing performance, effectively preventing the convection of hot and cold air. The profiles have high strength and do not deform even after long-term use. The material is recyclable. Corrosion-resistant and with stable performance over a long period.

Wooden window profiles: They have good natural insulation performance but are prone to cracking and deformation in humid environments, are susceptible to moisture, and have a rapid deterioration in sealing performance. The procurement and maintenance costs are high. Regular anti-corrosion, moisture-proofing, and maintenance are required.

PVC window profiles: The procurement cost is low, and the heat insulation and heat preservation performance are excellent. The profiles are lightweight, easy to process, and install. However, they have poor heat resistance. When exposed to high temperatures for a long time, they will age and become brittle, resulting in a decrease in insulation effect. In the later stage, frequent replacement of accessories is required, and the maintenance cost will increase year by year.

Stainless steel window profiles: Extremely strong and highly resistant to impact. However, they have high thermal conductivity, resulting in poor energy efficiency and rapid heat transfer between indoors and outdoors. Non-304/316 stainless steel models are prone to rust, affecting both appearance and sealing performance. The procurement cost is high, the long-term energy-saving loss is significant, and the maintenance cost is relatively high.

Energy Efficiency Aluminum Window Profile FAQ

Q: What are the benefits of installing aluminum windows in terms of energy efficiency?A: Aluminum windows are renowned for their excellent insulation properties, which help reduce heat loss and enhance the insulation of the house. They are also durable, have low maintenance costs, and are easy to recycle.

Q: How are aluminium profile windows different from other types of windows in terms of energy efficiency?

A: Aluminium windows, with modern technologies such as insulation breaks and high-performance glass, have outstanding energy-saving performance. Although PVC windows usually have better insulation properties due to their non-conductive nature, when properly configured, high-quality aluminium window systems can achieve, and even surpass, the insulation performance of PVC windows.

Q: Can architectural aluminum windows help me reduce energy costs?

A: Yes, installing aluminum windows can enhance the insulation of the house, reduce heat loss, and thereby help you lower energy expenses. Aluminum windows have excellent insulation properties, helping maintain a comfortable indoor temperature year-round.

Q: Why are aluminium profile windows considered as environmentally friendly and energy-saving materials?

A: Aluminium windows are regarded as environmentally friendly products for two reasons: Firstly, aluminium is a highly sustainable material that can be infinitely recycled without losing its quality. Secondly, they have a long service life of over 20 years, reducing the energy waste from frequent replacements and aligning with the concept of green buildings.

Q: Do high-rise residential aluminum windows have other advantages besides energy saving?

A: High-rise residential buildings have strict requirements for the wind resistance and sealing performance of doors and windows. Aluminum windows are highly durable and less prone to deformation. They can withstand strong winds and also block outdoor noise and hot/cold air. This not only saves energy but also enhances living comfort.

Q: Are you a reliable supplier of architectural aluminum window profiles?

A: Yes, Shenghai Aluminum has over 15 years of experience. We have completed more than 50 window and door profile projects. For more information, please contact us.