What Are Problems With Aluminum Profile Surfaces

Updated: 17 May 2024

Many factors affect the surface quality of aluminum alloy profiles. When there is a problem with the surface quality of the profile, such as "slag inclusion", the first thing to check is the quality of the ingot; if the surface has serious extrusion stripes and the surface is rough, the first thing to check is the quality of the mold.

Some surface quality problems can be solved, but some surface quality problems cannot be solved by simply looking at the ingot and mold to find the cause because one of the important factors affecting the surface quality of the profile is directly related to the extrusion process of the profile.

It is generally believed that slag inclusions in ingots cause slag inclusions and scratches on the surface of profiles. However, slag inclusions and scratches are related to the lax process control of profiles in the actual production process.

During extrusion, the surface of the ingot must be strictly controlled and cleaned. Suppose there are some waste aluminum chips or impurities on the surface of the ingot that need to be cleaned properly. In that case, these impurities will float on the surface of the profile or hang on the mold working belt during high-temperature extrusion, which will cause slag inclusions or scratches on the surface of the profile.

Solution

Daily cleaning

Check regularly

Scrapped molds and mold pads must be removed and replaced in time.

Pressure residual control

If the pressure residue is too small, a portion of the remaining oxides and impurities will flow into the die holes, which will also scratch the surface of the profile or cause slag inclusions during continuous extrusion.

Causes

After the mold temperature exceeds 450 degrees Celsius and the extreme heat time exceeds 6 hours, the surface of the profile extruded using a standard and reasonable extrusion process has obvious extrusion streaks and serious surface roughness, and the profile is dull.

The reason for this defect is that the mold heating time is too long and the mold temperature is high. The hardness of the mold's working belt's nitride layer is damaged. The hardness of the working belt is reduced and uneven. The friction force generated when the metal passes through the die hole will be relatively large. Large, serious flow velocity unevenness occurs between metals, which will also cause surface extrusion streaks and serious surface roughness.

Solution

Lowering the mold heating temperature and shortening the heating time can effectively eliminate and reduce the occurrence of extrusion streaks.

For example, when extruding profiles with thin wall thickness and complex cross-sections, the die temperature is low and it is easy to block the mold during extrusion. The ingot temperature can be appropriately increased to 500 to 520 degrees Celsius to solve the problem of complex profile forming and avoid the high temperature of the mold. Causes squeeze streaks.

The optimal temperature control of the mold should be to be able to extrude the profile from the mold. The lower the mold temperature, the better the surface quality of the extruded profile and the higher the brightness of the profile.

White corrosion spots sometimes appear on the surface of the profile during the extrusion process. Small pits appear on the surface of the profile after surface anodized treatment. These are corrosion spots caused by the extrusion process.

The reason for this phenomenon is that the surface temperature of the profile is high during extrusion and the surface of the profile is burned. It is caused by the temperature of the mold and ingot being too high or the extrusion speed being too fast.

Causes of bubble formation

Surface bubbles often appear in profiles during the extrusion process. The causes of bubbles are related to the looseness of the ingot, central cracks and the gas volume inside the ingot.

However, bubbles may also occur if the extrusion process is not strictly controlled, such as uneven pressure relief on the end face of the mold, too small residual pressure, large slopes at both ends of the ingot, unclean cleaning of the extrusion barrel, damage to the inner wall of the extrusion barrel, etc.

If the exhaust during the extrusion process is not good, air will be trapped inside the metal, which will also cause bubbles to appear on the surface of the profile.

Solution

In addition to solving the problem of ingot quality, bubbles can be generated by reducing the extrusion speed, reasonably increasing the residual length, and strictly timing equipment maintenance.

Some surface quality problems can be solved, but some surface quality problems cannot be solved by simply looking at the ingot and mold to find the cause because one of the important factors affecting the surface quality of the profile is directly related to the extrusion process of the profile.

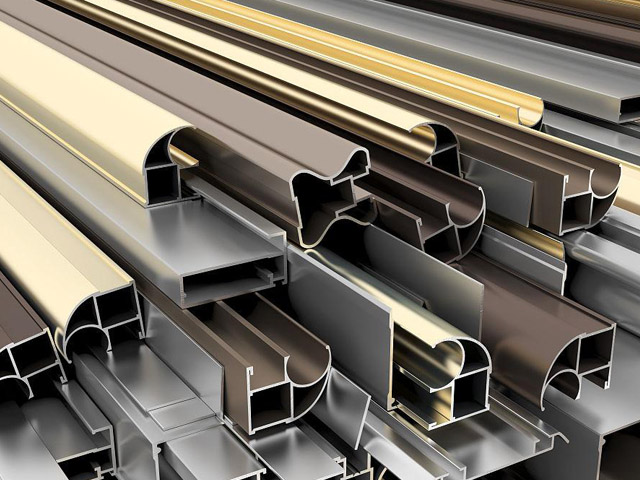

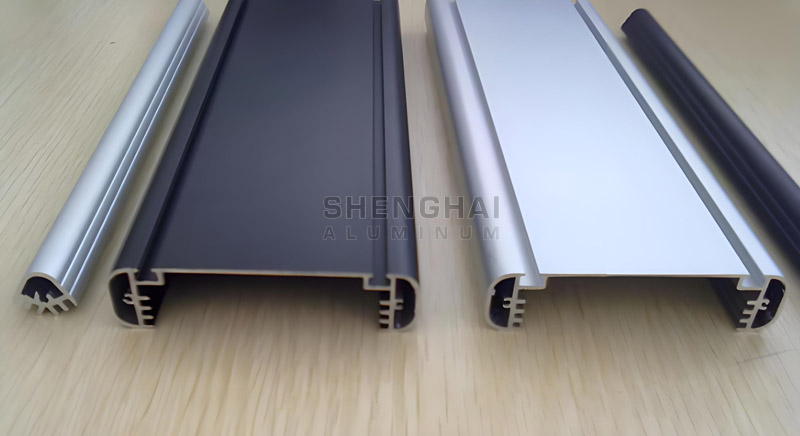

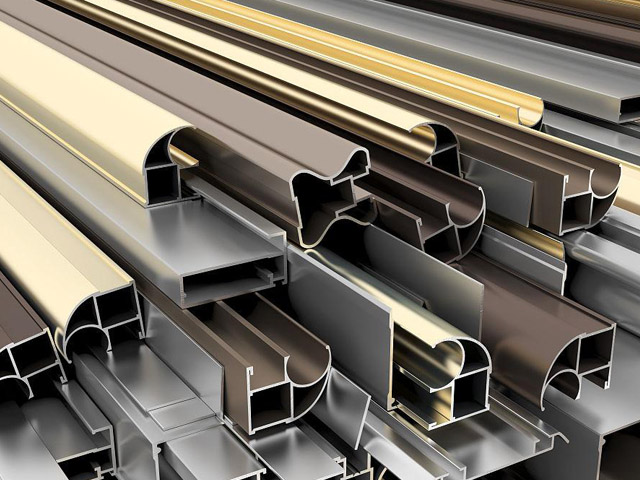

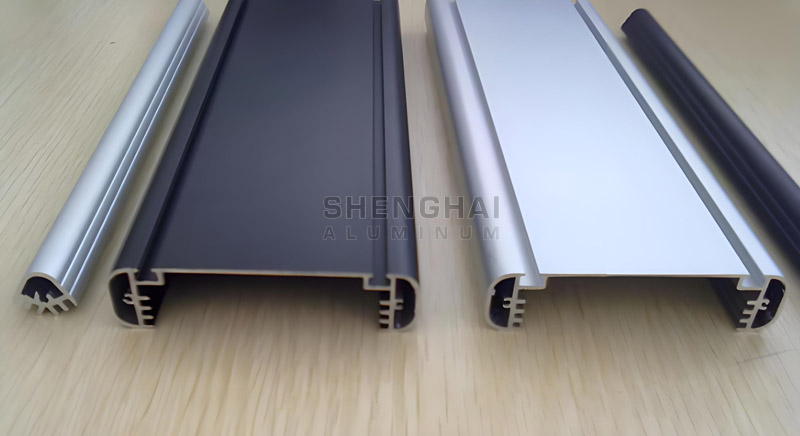

Common profile surface defects

Generally, the surface quality defects of aluminum alloy profiles include slag inclusions, scratches, extrusion streaks, surface roughness, corrosion spots and bubbles, etc.

These surface defects will affect the profile's quality, and severe defects will cause the profile to be scrapped. These defects are closely related to the control of processing technology.1. Slag inclusions and scratches

CausesIt is generally believed that slag inclusions in ingots cause slag inclusions and scratches on the surface of profiles. However, slag inclusions and scratches are related to the lax process control of profiles in the actual production process.

During extrusion, the surface of the ingot must be strictly controlled and cleaned. Suppose there are some waste aluminum chips or impurities on the surface of the ingot that need to be cleaned properly. In that case, these impurities will float on the surface of the profile or hang on the mold working belt during high-temperature extrusion, which will cause slag inclusions or scratches on the surface of the profile.

Solution

Daily cleaning

Clean some impurities on the inner wall of the extrusion barrel to prevent impurities from being rolled into the die hole. The extrusion barrel must be free of serious wear and controlled temperature to avoid overcooling or overheating.

Check regularly

Scrapped molds and mold pads must be removed and replaced in time.

Pressure residual control

If the pressure residue is too small, a portion of the remaining oxides and impurities will flow into the die holes, which will also scratch the surface of the profile or cause slag inclusions during continuous extrusion.

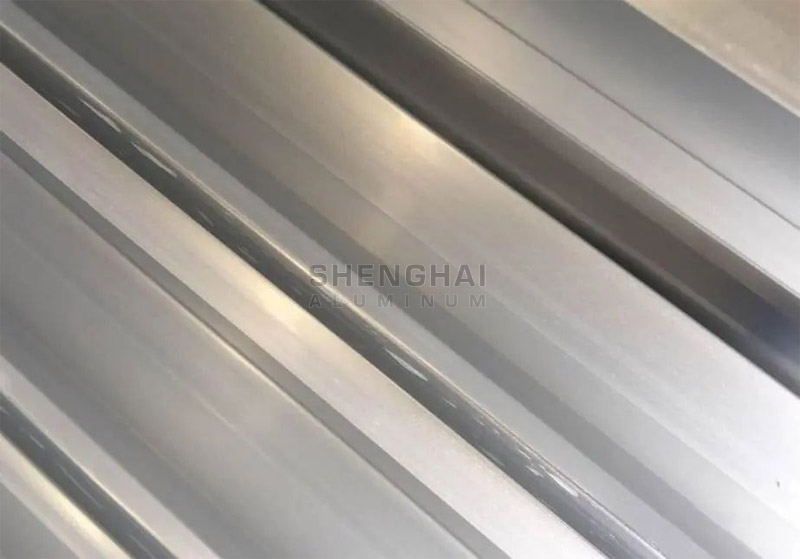

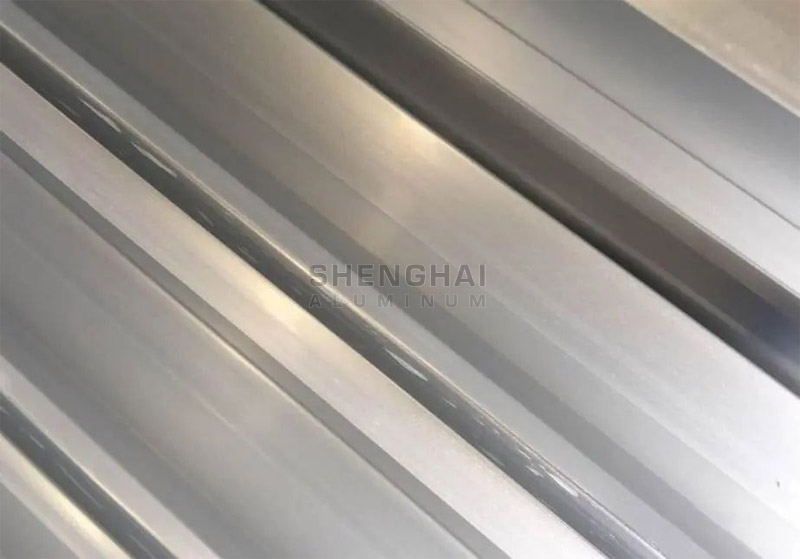

2. Extrude streaks

The causes of extrusion streaks and surface roughness are closely related to the design of the extrusion die and the quality of die processing. Analysis of the alloy composition of molds and ingots can find some causes of defects. Still, in the actual production process, some extrusion streaks and surface roughness are caused by control errors in the extrusion process.Causes

After the mold temperature exceeds 450 degrees Celsius and the extreme heat time exceeds 6 hours, the surface of the profile extruded using a standard and reasonable extrusion process has obvious extrusion streaks and serious surface roughness, and the profile is dull.

The reason for this defect is that the mold heating time is too long and the mold temperature is high. The hardness of the mold's working belt's nitride layer is damaged. The hardness of the working belt is reduced and uneven. The friction force generated when the metal passes through the die hole will be relatively large. Large, serious flow velocity unevenness occurs between metals, which will also cause surface extrusion streaks and serious surface roughness.

Solution

Lowering the mold heating temperature and shortening the heating time can effectively eliminate and reduce the occurrence of extrusion streaks.

For example, when extruding profiles with thin wall thickness and complex cross-sections, the die temperature is low and it is easy to block the mold during extrusion. The ingot temperature can be appropriately increased to 500 to 520 degrees Celsius to solve the problem of complex profile forming and avoid the high temperature of the mold. Causes squeeze streaks.

The optimal temperature control of the mold should be to be able to extrude the profile from the mold. The lower the mold temperature, the better the surface quality of the extruded profile and the higher the brightness of the profile.

3. Corrosion points and bubbles

Causes of corrosion pointsWhite corrosion spots sometimes appear on the surface of the profile during the extrusion process. Small pits appear on the surface of the profile after surface anodized treatment. These are corrosion spots caused by the extrusion process.

The reason for this phenomenon is that the surface temperature of the profile is high during extrusion and the surface of the profile is burned. It is caused by the temperature of the mold and ingot being too high or the extrusion speed being too fast.

Causes of bubble formation

Surface bubbles often appear in profiles during the extrusion process. The causes of bubbles are related to the looseness of the ingot, central cracks and the gas volume inside the ingot.

However, bubbles may also occur if the extrusion process is not strictly controlled, such as uneven pressure relief on the end face of the mold, too small residual pressure, large slopes at both ends of the ingot, unclean cleaning of the extrusion barrel, damage to the inner wall of the extrusion barrel, etc.

If the exhaust during the extrusion process is not good, air will be trapped inside the metal, which will also cause bubbles to appear on the surface of the profile.

Solution

In addition to solving the problem of ingot quality, bubbles can be generated by reducing the extrusion speed, reasonably increasing the residual length, and strictly timing equipment maintenance.