What is an Aluminum Trim

Updated: 30 Sep 2025

Aluminum trim, as a high-performance and aesthetically pleasing finishing material, stands out among numerous options and is increasingly favored by designers, builders, and furniture manufacturers. Made from high-quality aluminum alloy through extrusion and various surface treatments, it not only provides edging, protection, and decoration, but also offers advantages such as lightweight, durability, and environmental friendliness. Whether used for wall panel transitions, door and window trim, or furniture edging, aluminum trim provides a comprehensive solution that combines beauty and functionality for any project.

Aluminum has stable chemical properties and naturally forms a dense oxide layer on its surface in air, which protects the underlying metal from further corrosion. Compared to steel, which rusts easily and requires regular maintenance, and stone, which weathers and cracks easily (salt spray in coastal areas accelerates this process), aluminum profiles offer superior corrosion resistance. Ordinary aluminum profiles exposed to dry inland environments can last for over 20 years; even in humid environments, untreated aluminum profiles can maintain their integrity for over 10 years. Furthermore, surface treatments such as anodizing and powder coating further enhance the durability and lifespan of aluminum trim.

While various materials for decorative trim have their own characteristics, aluminum offers a more comprehensive advantage in terms of durability, aesthetics, and environmental friendliness. For projects that prioritize long-term stability and aesthetics, aluminum decorative trim is undoubtedly a more worthwhile choice.

Lightweight and Durable

Aluminum alloy boasts high strength and low density, resulting in a lightweight material that can withstand the stresses of daily use without adding unnecessary weight to the structure.

Good Stability

Aluminum trim strips can effectively resist oxidation and humid environments. Especially after surface treatment, they can maintain stable performance over a long period. In addition, they also have impact-resistant characteristics.

Excellent Aesthetics

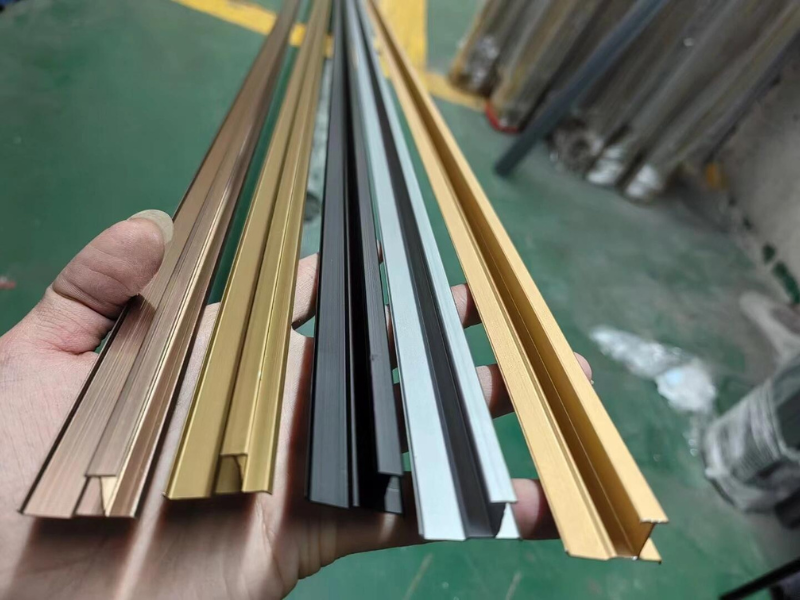

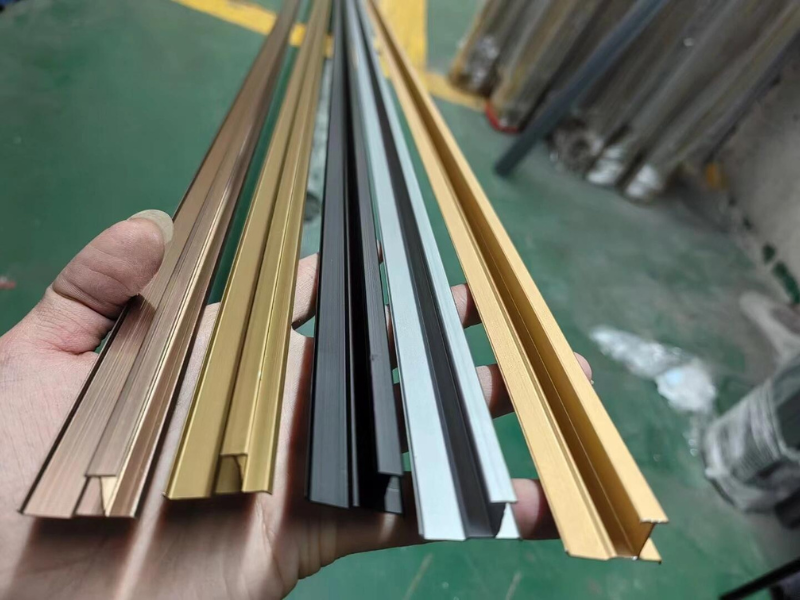

Aluminum profiles offer outstanding decorative qualities. Through processes such as brushed finish, sandblasting, and wood grain transfer, a wide range of textures and colors can be achieved. They can serve as decorative accents, concealing the internal structure of door and window frames, and also facilitate color transitions and coordination in interior design. The skillful use of metal profiles can harmoniously blend contrasting colors, adding a unique decorative touch to any space.

Easy and Efficient Installation

Installing aluminum profiles is extremely simple and efficient. It requires minimal labor and materials, resulting in easy and quick installation. This ease of installation not only improves construction efficiency but also reduces costs.

Wide Range of Applications

Aluminum trim profiles have a wide range of applications. Whether in the construction and decoration industry, or in artistic interiors, hotels, clubs, and other venues, aluminum trim profiles offer distinctive decorative effects. Their elegant and sophisticated appearance enhances the overall aesthetic appeal of any space.

U Channel Aluminum Trim

There are usually two types of U channel aluminum trims: symmetrical U-shaped with equal sides and asymmetrical U-shaped with sides of different lengths. In addition to edging and embedding functions, the symmetrical U-shaped aluminum trim can also serve as a channel for LED strips. The longer side of the asymmetrical U-shaped aluminum trim usually functions to provide extra protection or to cover uneven surfaces. Both types are suitable for wooden doors, cabinet doors, feature walls, chair rails, and other wall decorations.

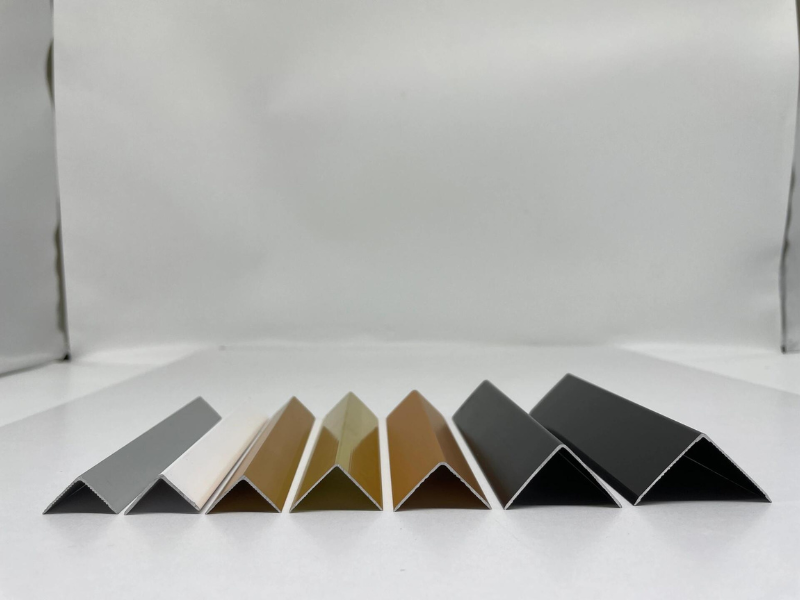

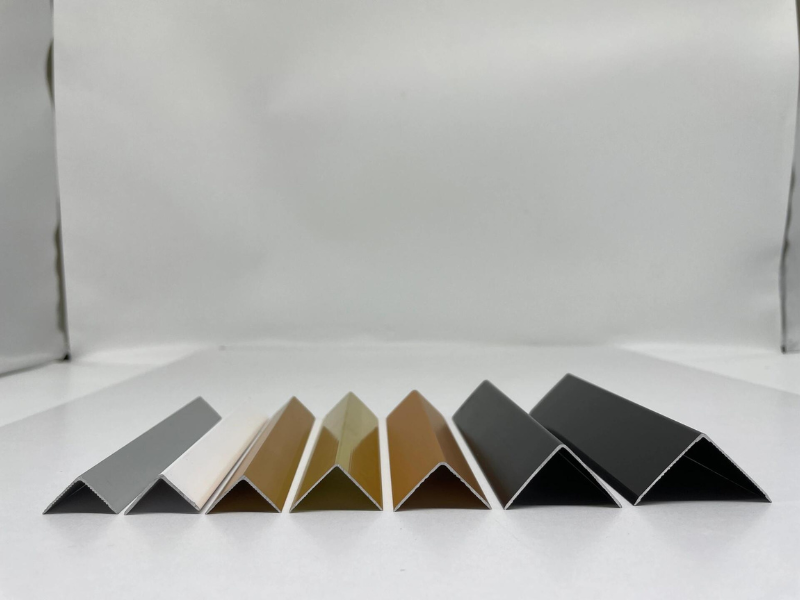

L-Shaped Aluminum Trim

L-shaped edging trim is widely used for wall edging, corner protection, and step edges, serving both protective and decorative purposes.

T-Shaped Aluminum Trim

T-shaped aluminum trim has good transitional and protective functions. It is commonly used at tile edges (connecting different tiles or protecting tile edges) and furniture. There are many styles of T-shaped trim, and to ensure stability after installation, the embedded part is usually designed with barbs or serrated shapes.

Aluminum Cap Channel Edge

Aluminum cap channel edge is commonly used in architectural decoration, for example, as a decorative separation between materials such as gypsum boards and tiles.

J-Shaped Aluminum Trim

J-shaped aluminum trim is widely used in the field of architectural decoration.

Z Channel Aluminum Edging

Z channel edge has a wide range of applications, such as for display areas and wall panel decoration.

H-Shaped Aluminum Trim

H-shaped aluminum trim is widely used in furniture, doors and windows, decoration, industry, and construction.

Round Corner Aluminum Trim

Our round corner aluminum trim is commonly used for LED strip installation. In addition, it can also be used for tiles, cabinets, furniture, and other decorative applications.

Installing aluminum trim strips is quick and easy. Here's a step-by-step guide for the standard installation process.

1. Preparation

Choose high-quality strips with surfaces free of scratches and dents, and ensure the specifications and dimensions are appropriate. Before installing aluminum decorative strips, clean the surfaces and ensure the base is flat and dry to facilitate a firmer installation. At the same time, prepare some tools, such as a fine-toothed saw for cutting, tape measure, level, drill bits, screws, file, adhesive, and personal protective equipment.

2. Accurate measurement

Use a tape measure to measure the required length; it's recommended to measure several times to avoid errors. Also, mark the measurements with a marker pen.

3. Cutting the Trim Strip

Cut the trim strip along the marked line using a fine-toothed saw or metal shears, keeping the cut straight. Smooth the cut edges with sandpaper or a file to remove any sharp edges. For corners, cut at a 45° angle for a neat and seamless fit.

4. Positioning and Trial Fit

4. Positioning and Trial Fit

Place the cut trim strip in its intended position and check the length and angle. Use a level to ensure it is straight.

5. Fixing Method Selection

If using adhesive, apply a suitable amount of strong construction adhesive evenly to the back of the decorative strip. Then gently press it onto the wall or furniture surface and hold it in place for a few minutes until it is initially adhered. If using clips, drill holes at the marked locations and insert expansion bolts.Use screws or special clips to secure the decorative strip. Ensure the screw heads are flush or hidden to maintain a neat appearance.

6. Seaming and Finishing

When multiple sections of decorative strip are used for longer walls or cabinets, ensure they are aligned precisely and the seams are as tight as possible. If necessary, apply a small amount of sealant or filler to the seams for a more seamless look.

7. Inspection and Cleaning

After fixing, use a level to check the flatness again to ensure accuracy and allow for any necessary adjustments. Wipe off any excess glue or dust, and carefully inspect the area to ensure there are no sharp edges or debris that could cause scratches later.

It is worth noting that if installed in humid or high-temperature environments, such as kitchens and bathrooms, it is recommended to use a combination of adhesive and screws for fixing, which is more secure.

Why choose aluminum trim over other materials?

Aluminum has stable chemical properties and naturally forms a dense oxide layer on its surface in air, which protects the underlying metal from further corrosion. Compared to steel, which rusts easily and requires regular maintenance, and stone, which weathers and cracks easily (salt spray in coastal areas accelerates this process), aluminum profiles offer superior corrosion resistance. Ordinary aluminum profiles exposed to dry inland environments can last for over 20 years; even in humid environments, untreated aluminum profiles can maintain their integrity for over 10 years. Furthermore, surface treatments such as anodizing and powder coating further enhance the durability and lifespan of aluminum trim.

While various materials for decorative trim have their own characteristics, aluminum offers a more comprehensive advantage in terms of durability, aesthetics, and environmental friendliness. For projects that prioritize long-term stability and aesthetics, aluminum decorative trim is undoubtedly a more worthwhile choice.

Features of Aluminum Trim

Lightweight and Durable

Aluminum alloy boasts high strength and low density, resulting in a lightweight material that can withstand the stresses of daily use without adding unnecessary weight to the structure.

Aluminum trim strips can effectively resist oxidation and humid environments. Especially after surface treatment, they can maintain stable performance over a long period. In addition, they also have impact-resistant characteristics.

Excellent Aesthetics

Aluminum profiles offer outstanding decorative qualities. Through processes such as brushed finish, sandblasting, and wood grain transfer, a wide range of textures and colors can be achieved. They can serve as decorative accents, concealing the internal structure of door and window frames, and also facilitate color transitions and coordination in interior design. The skillful use of metal profiles can harmoniously blend contrasting colors, adding a unique decorative touch to any space.

Easy and Efficient Installation

Installing aluminum profiles is extremely simple and efficient. It requires minimal labor and materials, resulting in easy and quick installation. This ease of installation not only improves construction efficiency but also reduces costs.

Wide Range of Applications

Aluminum trim profiles have a wide range of applications. Whether in the construction and decoration industry, or in artistic interiors, hotels, clubs, and other venues, aluminum trim profiles offer distinctive decorative effects. Their elegant and sophisticated appearance enhances the overall aesthetic appeal of any space.

Common Types of Aluminum Trim

U Channel Aluminum Trim

There are usually two types of U channel aluminum trims: symmetrical U-shaped with equal sides and asymmetrical U-shaped with sides of different lengths. In addition to edging and embedding functions, the symmetrical U-shaped aluminum trim can also serve as a channel for LED strips. The longer side of the asymmetrical U-shaped aluminum trim usually functions to provide extra protection or to cover uneven surfaces. Both types are suitable for wooden doors, cabinet doors, feature walls, chair rails, and other wall decorations.

L-Shaped Aluminum Trim

L-shaped edging trim is widely used for wall edging, corner protection, and step edges, serving both protective and decorative purposes.

T-shaped aluminum trim has good transitional and protective functions. It is commonly used at tile edges (connecting different tiles or protecting tile edges) and furniture. There are many styles of T-shaped trim, and to ensure stability after installation, the embedded part is usually designed with barbs or serrated shapes.

Aluminum Cap Channel Edge

Aluminum cap channel edge is commonly used in architectural decoration, for example, as a decorative separation between materials such as gypsum boards and tiles.

J-Shaped Aluminum Trim

J-shaped aluminum trim is widely used in the field of architectural decoration.

Z Channel Aluminum Edging

Z channel edge has a wide range of applications, such as for display areas and wall panel decoration.

H-Shaped Aluminum Trim

H-shaped aluminum trim is widely used in furniture, doors and windows, decoration, industry, and construction.

Round Corner Aluminum Trim

Our round corner aluminum trim is commonly used for LED strip installation. In addition, it can also be used for tiles, cabinets, furniture, and other decorative applications.

How to Install Aluminum Trim?

Installing aluminum trim strips is quick and easy. Here's a step-by-step guide for the standard installation process.

1. Preparation

Choose high-quality strips with surfaces free of scratches and dents, and ensure the specifications and dimensions are appropriate. Before installing aluminum decorative strips, clean the surfaces and ensure the base is flat and dry to facilitate a firmer installation. At the same time, prepare some tools, such as a fine-toothed saw for cutting, tape measure, level, drill bits, screws, file, adhesive, and personal protective equipment.

Use a tape measure to measure the required length; it's recommended to measure several times to avoid errors. Also, mark the measurements with a marker pen.

3. Cutting the Trim Strip

Cut the trim strip along the marked line using a fine-toothed saw or metal shears, keeping the cut straight. Smooth the cut edges with sandpaper or a file to remove any sharp edges. For corners, cut at a 45° angle for a neat and seamless fit.

Place the cut trim strip in its intended position and check the length and angle. Use a level to ensure it is straight.

5. Fixing Method Selection

If using adhesive, apply a suitable amount of strong construction adhesive evenly to the back of the decorative strip. Then gently press it onto the wall or furniture surface and hold it in place for a few minutes until it is initially adhered. If using clips, drill holes at the marked locations and insert expansion bolts.Use screws or special clips to secure the decorative strip. Ensure the screw heads are flush or hidden to maintain a neat appearance.

6. Seaming and Finishing

When multiple sections of decorative strip are used for longer walls or cabinets, ensure they are aligned precisely and the seams are as tight as possible. If necessary, apply a small amount of sealant or filler to the seams for a more seamless look.

7. Inspection and Cleaning

After fixing, use a level to check the flatness again to ensure accuracy and allow for any necessary adjustments. Wipe off any excess glue or dust, and carefully inspect the area to ensure there are no sharp edges or debris that could cause scratches later.

It is worth noting that if installed in humid or high-temperature environments, such as kitchens and bathrooms, it is recommended to use a combination of adhesive and screws for fixing, which is more secure.

Shenghai Aluminum is an aluminum extrusion supplier focused on the export of aluminum decorative trim strips. We provide a variety of surface treatment processes and support custom designs based on your drawings. With years of experience and stable supply capabilities, we can be your trusted partner. Please contact us now to get samples or customized solutions for you.