Aviation-Grade Solar Aluminum: Lightweight, Durable, High-Strength

Color:

Sliver Anodizing or Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

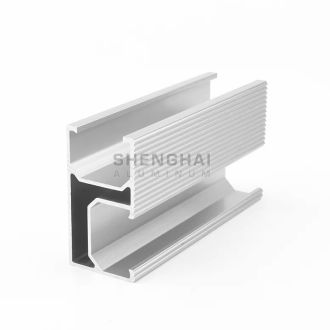

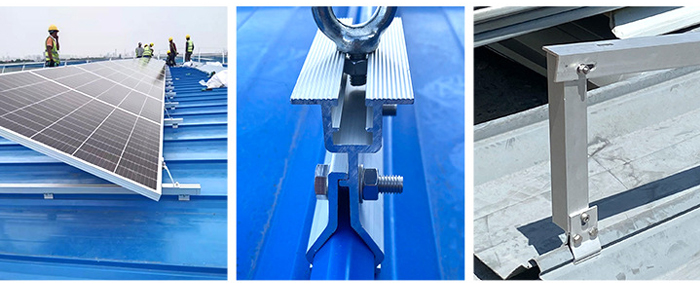

Premium Aviation-Grade Solar Aluminum Alloy: Engineered for ExcellenceThis high-performance solar aluminum material is designed to meet the rigorous demands of modern solar energy systems. Its exceptional qualities include lightweight construction, superior corrosion resistance, and high strength, ensuring long-term durability and reliability. Additionally, it boasts excellent electrical and thermal conductivity, making it ideal for efficient energy transfer and system performance. With a lifespan of 30-50 years or more, this material is not only sustainable but also offers significant cost savings over time. Perfectly tailored for the U.S. market, it is a top-tier choice for solar panel frames, mounting systems, and other critical components, delivering unmatched quality and environmental benefits.

PV Solar Panel Aluminum L Shape Corner Size

40mm x 40mm x 3mm,

50mm x 50mm x 5mm,

30mm x 30mm x 2mm,

60mm x 60mm x 6mm, or customized.

Product Feature:

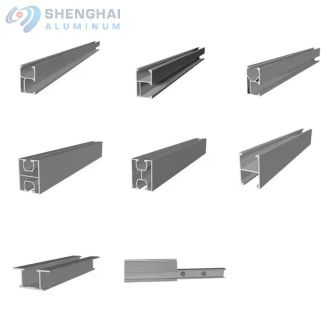

Advantage of aluminum rail solar panel

1. Corrosion resistance and strong oxidation resistance;

2. Strong strength and firmness;

3. Strong tensile strength;

4. High elasticity, rigidity and metal fatigue value;

5. Convenient transportation and installation, even if the surface is scratched, it will not oxidize, and does not affect performance;

6. It can adapt to various environments through convenient selection of different materials;

7. The service life is more than 25 years.

Our Factory

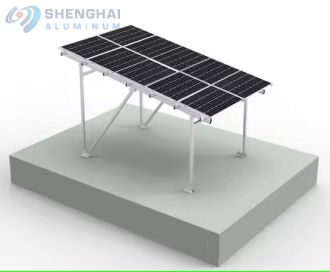

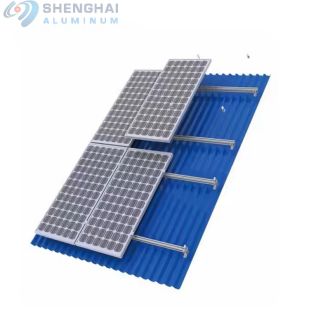

Product Application

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message