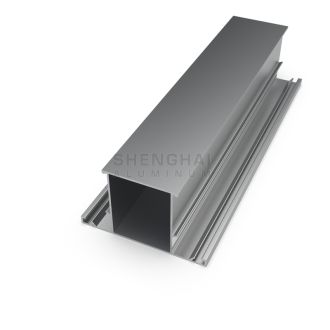

Broken Bridge Aluminum Alloy Doors and Windows | 6063-T5 | Thermal Break | Factory Direct Supply

Model Number:

6061 6063 T5 T6

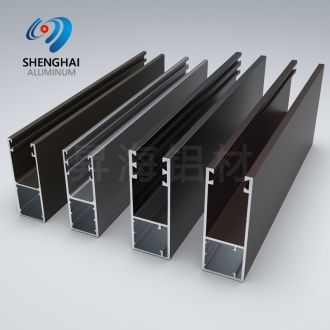

Color:

Sliver Anodizing or Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

Broken bridge aluminum alloy doors and windows | Direct supply from the source factory, quality assuranceWe focus on the research and development and manufacturing of broken bridge aluminum alloy doors and windows, using 6063-T5 original aluminum. The products have multiple advantages such as strong wind pressure resistance, corrosion resistance, and excellent thermal insulation performance. They are ideal for modern residential and commercial buildings.

Core advantages:

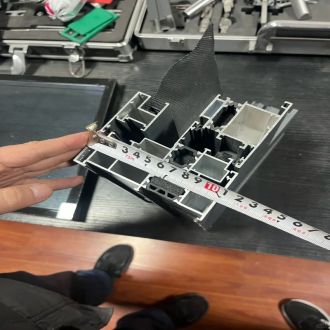

Preferred materials: 6063-T5 aluminum, uniform wall thickness throughout the body, high strength and long life.

Stable structure: cavity structure design enhances wind pressure resistance and remains stable and non-deformed in the face of severe weather.

Excellent thermal insulation performance: The design of the inner fin multi-cavity insulation strip and the isotherm is more vertical, effectively reducing heat conduction and improving energy efficiency.

Sealing upgrade: Equipped with an integrated microwave vulcanized welding strip, the strip has a high degree of fit, is dustproof and waterproof, and improves air tightness and water tightness.

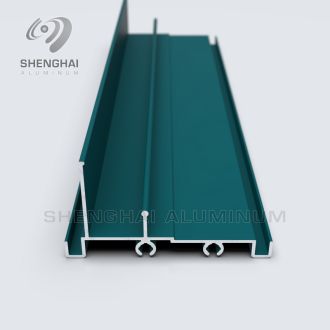

Anti-corrosion treatment: The surface has been treated with multiple anti-corrosion processes, has strong weather resistance, and is suitable for a variety of climate environments.

Intelligent drainage design: built-in drip strip system, rainwater can be discharged in time to avoid water leakage and protect the structure.

Support customized services: thickness, molds, and hardware accessories can be customized according to customer needs to meet personalized project needs.

We are the source factory of aluminum alloy doors and windows, providing stable supply and flexible customization solutions, and are committed to creating high-quality, reliable and safe door and window products for global customers.

Take action! Contact us now to get professional advice and accurate quotations, so that your project can start the road to high quality from now on!

Product application scenarios

Our customers from all over the world

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

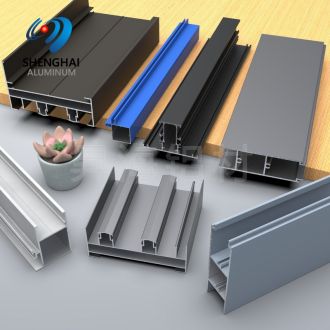

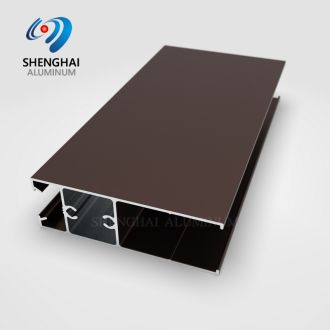

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

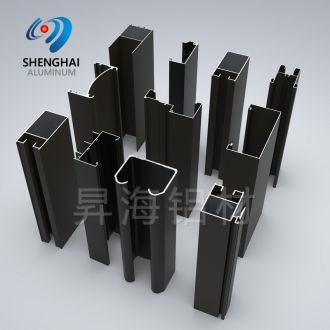

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message