How to choose the right aluminum alloy doors and windows

Doors and windows are an indispensable part of a house. When it comes to doors and windows, many people will choose aluminum alloy doors and windows. Aluminum alloy doors and windows have very good decorative effects and have performance characteristics such as wind pressure resistance, aesthetics, water tightness, sound insulation, and heat preservation. Therefore, aluminum alloy door and window profiles have become the key objects of home decoration. When choosing doors and windows, we should pay attention to its material, thickness, color, flatness, glossiness, and degree of oxidation.

According to the strength

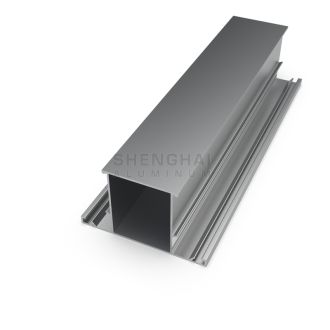

Both the tensile strength (157 Newtons per square millimeter) and the yield strength (108 Newtons per square millimeter) should be met. When purchasing, you can bend the aluminum alloy profile moderately with your hands, and it should return to its original shape after letting go.

According to the chromaticity

The same aluminum alloy profile should have a constant hue. It is not appropriate to purchase if the color difference is noticeable.

According to the flatness

Look at the aluminum alloy profile’s surface; there shouldn’t be any bulges or depressions.

According to the glossiness

Aluminum alloy doors and windows should avoid purchasing aluminum alloy profiles with open air bubbles (white spots) and ash residue (black spots) on the surface, as well as obvious defects such as cracks, burrs, and peeling.

According to the oxidation degree

The oxide film thickness should reach 10 microns. When purchasing, you can lightly scratch the profile’s surface to check if the oxide deposit can be removed.

If you have special needs, please contact us. As a professional aluminum product supplier, Shenghai supplies a variety of finished products, from architectural profile systems to industrial aluminum products, mainly including aluminum doors and windows, aluminum curtain walls, aluminum sun rooms, aluminum garden gates, garden fences, aluminum handrails, aluminum upstairs, all-aluminum furniture, aluminum shelves, etc. Please tell us your needs, we are very happy to serve you.

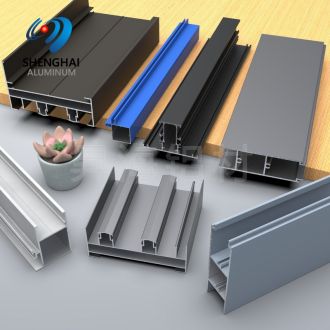

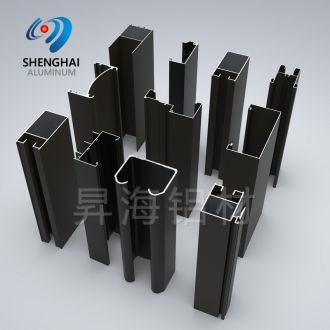

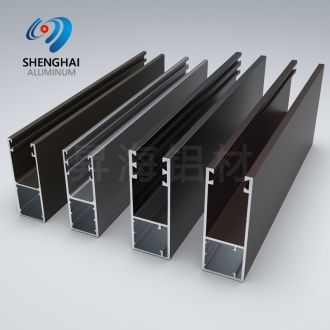

Grade: Aluminium alloy 6061, 6063

Material: Aluminium alloy T5/T6

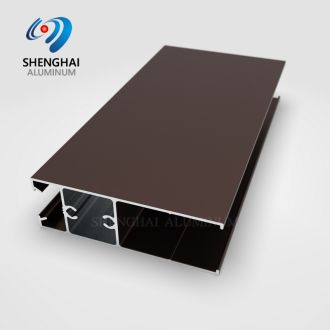

Color: Powder coating (white, bronze, charcoal) and anodized natural

Surface treatment: Mill finish, powder coating, anodized

Length: 5.8m/5.85m/customization

Thickness: 0.4mm and up

Application: Sliding glass doors for patios, balconies, and modern living spaces

Features:

Energy-efficient and space-saving design

Excellent noise-proof capabilities for a quiet environment

Durable and corrosion-resistant with a sleek, frosted aluminum frame

Easy installation and customizable to fit any space

Product Application

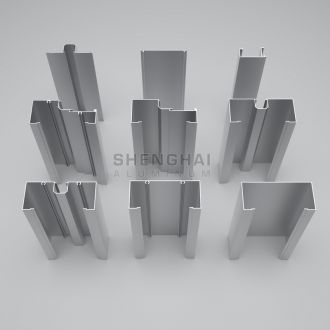

Commercial door and window

Residential door and window

Curtain walls

Furniture wardrobe and kitchen cabinet

Decoration profiles

Industrial window and door

Our Factory

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |