How To Choose Aluminum Window Profile For Coastal Home

Updated: 15 Dec 2025

Coastal homes, with their charming ocean views and comfortable climate, are among the most desirable residences. However, behind this highly sought-after living experience lies a challenge in building maintenance: salty, humid air, high humidity, and strong UV exposure will accelerate the aging of construction materials.

Whether in coastal areas or desert regions, aluminum window profiles are more capable of withstanding tests than other materials. Wooden window frames may rot, paint on steel may peel off, and some uPVC products may warp or fade over time. For window and door manufacturers who prioritize product durability, aesthetic quality, and long-term market competitiveness, choosing stable and reliable aluminum alloy profiles is a crucial foundation for improving overall window and door performance and brand value. Aluminum window frames shine brightly in the construction industry and possess numerous outstanding qualities. They can withstand the tests of extreme environments, handling everything from humid coasts to scorching deserts with ease. They will not warp or rust. Their slim-frame design maximizes the glass area, offering better natural lighting and improved visibility. Meanwhile, aluminum alloy is a recyclable material, which supports the development of environmentally friendly buildings. Most importantly, unlike wood or plastic, aluminum alloy requires almost no maintenance, thus reducing long-term costs.

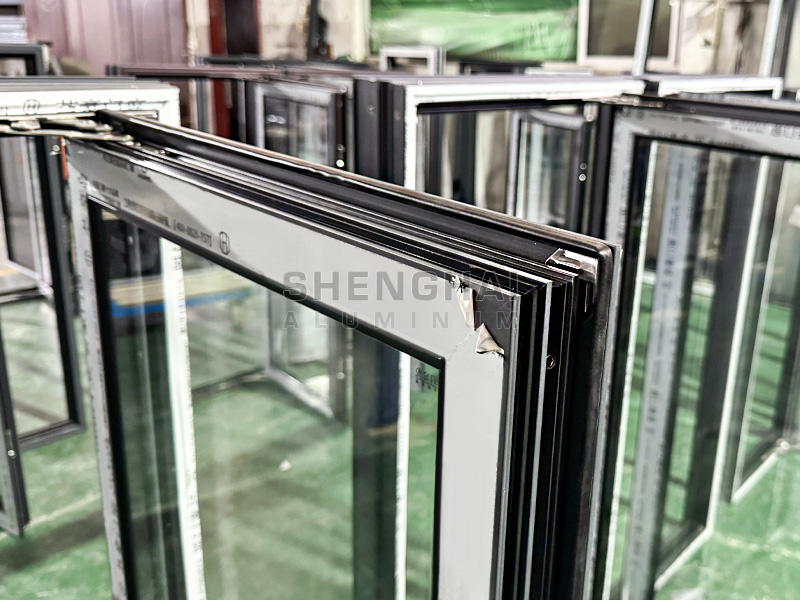

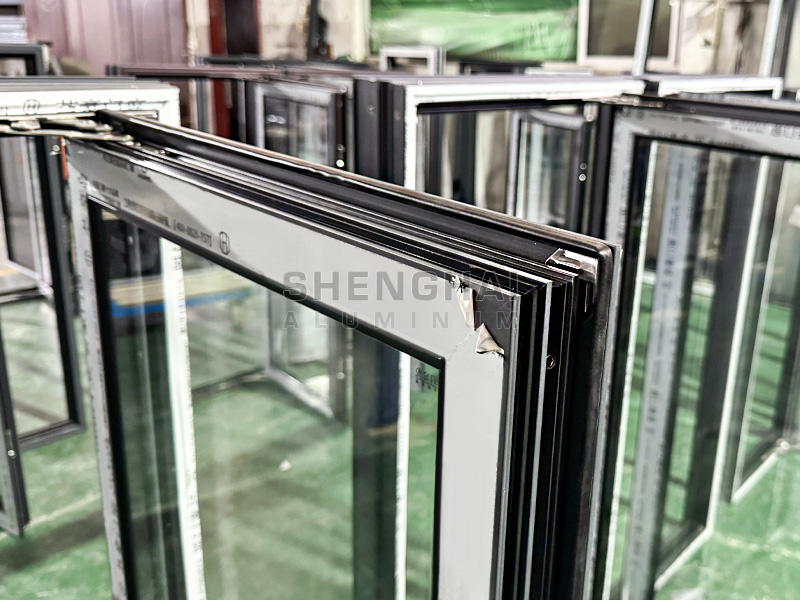

Aluminum alloy window frame profiles are widely used in residential and commercial buildings due to their high strength, flexible design, and excellent corrosion and deformation resistance.

Depending on usage scenarios and needs, they can be customized into various window configurations, including sliding, casement, inward-opening, and fixed windows. Compared to wood or uPVC, aluminum profiles do not rot, swell, or warp from moisture and do not require frequent repainting. This makes them an ideal material for humid environments and coastal regions.

Although aluminum window frame profiles are well-known for their durability and modern appearance, not all aluminum profiles can withstand the harsh environmental conditions of coastal regions. To ensure long-term performance, corrosion resistance, and reliable protection under extreme weather, it is crucial to choose aluminum window profiles specifically engineered for coastal environments.

Here are some essential recommendations for selecting the right aluminum window profiles for coastal homes:

At the same time, we offer a wide range of color options and support personalized color customization, enabling precise matches for architectural styles ranging from modern simplicity to classic elegance. This enables doors and windows not only to provide strong protection but also to add a refined aesthetic texture to the space.

Compared with powder coating, the color selection for anodizing is simpler (mainly in the original metallic color series), but it offers better durability and a delicate, high-end metallic luster, endowing aluminum Windows with a simple, elegant, modern texture. It can match various architectural styles without complex decoration. Daily maintenance requires only simple cleaning and minimal upkeep, keeping it smooth and bright for a long time.

At present, our European, North American, and Japanese customers, as well as those from South Korea, Australia, and other regions, all prefer anodized aluminum window extrusion, valuing its stable performance and long service life in harsh environments.

In addition, our powder coatings offer excellent durability and corrosion resistance and have been specifically optimized for coastal environments. Its surface texture is fine, and it will not fade even when exposed to strong ultraviolet rays and salty air for extended periods. Daily maintenance is extremely convenient - just dip a sponge in clean water and gently wipe it, and the window can maintain a clean and bright appearance for a long time. This ensures that your aluminium Windows not only remain aesthetically pleasing but also maintain reliable protective performance in harsh coastal climates.

After undergoing powder coating or anodizing, the corrosion resistance and UV resistance of aluminum window frames have been significantly enhanced. Even in the high-salt coastal areas and the humid, muggy southern environments, they are not prone to rust, aging, or fading. However, uPVC is prone to brittleness, yellowing, and cracking when exposed to prolonged sunlight, and its service life will be significantly shortened.

Aluminum alloy window frames support a wide range of color customization options, suitable for various architectural styles such as modern simplicity, light luxury, and retro, and can also create simple lines. The color options for uPVC window frames are relatively limited, and the profile lines are rather thick and heavy, with weak aesthetic appeal and style compatibility. Aluminum alloy window frames require little to no special maintenance. Meanwhile, aluminum alloy is an environmentally friendly and recyclable material. After being scrapped, it can be recycled and reprocessed, without generating excessive construction waste.

Aluminum alloy window frames support a wide range of color customization options, suitable for various architectural styles such as modern simplicity, light luxury, and retro, and can also create simple lines. The color options for uPVC window frames are relatively limited, and the profile lines are rather thick and heavy, with weak aesthetic appeal and style compatibility. Aluminum alloy window frames require little to no special maintenance. Meanwhile, aluminum alloy is an environmentally friendly and recyclable material. After being scrapped, it can be recycled and reprocessed, without generating excessive construction waste.

Overall, aluminum window profiles are the most suitable for coastal homes. The corrosion resistance and wind pressure resistance of aluminum extruded profiles are unmatched by other materials. Shenghai Aluminum has extensive experience in the aluminum door and window extrusion industry, and our clients come from the Middle East, Africa, Australia, Canada, Mexico, and other countries. If you would like to learn more about aluminum door and window profile solutions, please feel free to contact us for professional solutions.

Whether in coastal areas or desert regions, aluminum window profiles are more capable of withstanding tests than other materials. Wooden window frames may rot, paint on steel may peel off, and some uPVC products may warp or fade over time. For window and door manufacturers who prioritize product durability, aesthetic quality, and long-term market competitiveness, choosing stable and reliable aluminum alloy profiles is a crucial foundation for improving overall window and door performance and brand value. Aluminum window frames shine brightly in the construction industry and possess numerous outstanding qualities. They can withstand the tests of extreme environments, handling everything from humid coasts to scorching deserts with ease. They will not warp or rust. Their slim-frame design maximizes the glass area, offering better natural lighting and improved visibility. Meanwhile, aluminum alloy is a recyclable material, which supports the development of environmentally friendly buildings. Most importantly, unlike wood or plastic, aluminum alloy requires almost no maintenance, thus reducing long-term costs.

Why Choose Aluminum Window Profiles for Coastal Homes

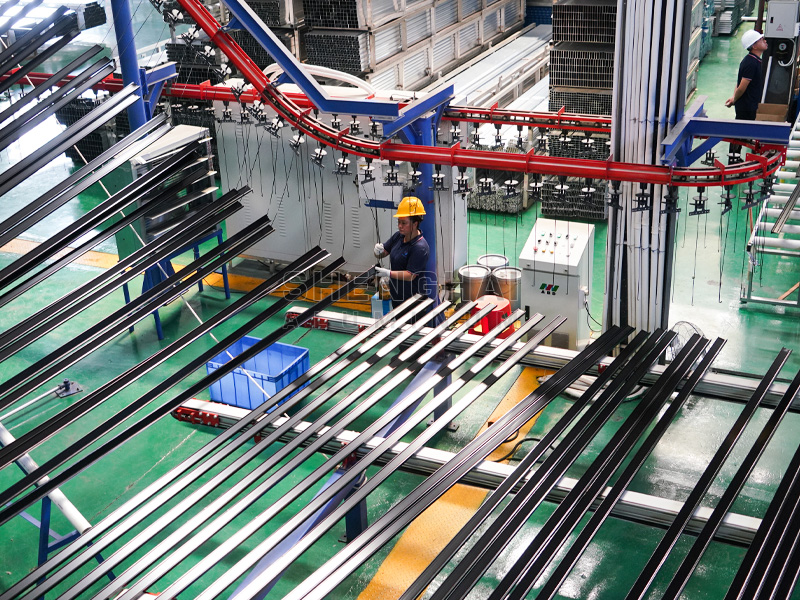

Aluminum window profiles are extruded metal frames designed to secure glass panels while providing structural support, reliable weatherproofing, and a sleek aesthetic appeal. These profiles are manufactured through a process called aluminum extrusion, in which heated aluminum billets are extruded through a precision die to form a specific cross-sectional shape.Aluminum alloy window frame profiles are widely used in residential and commercial buildings due to their high strength, flexible design, and excellent corrosion and deformation resistance.

Depending on usage scenarios and needs, they can be customized into various window configurations, including sliding, casement, inward-opening, and fixed windows. Compared to wood or uPVC, aluminum profiles do not rot, swell, or warp from moisture and do not require frequent repainting. This makes them an ideal material for humid environments and coastal regions.

Although aluminum window frame profiles are well-known for their durability and modern appearance, not all aluminum profiles can withstand the harsh environmental conditions of coastal regions. To ensure long-term performance, corrosion resistance, and reliable protection under extreme weather, it is crucial to choose aluminum window profiles specifically engineered for coastal environments.

Here are some essential recommendations for selecting the right aluminum window profiles for coastal homes:

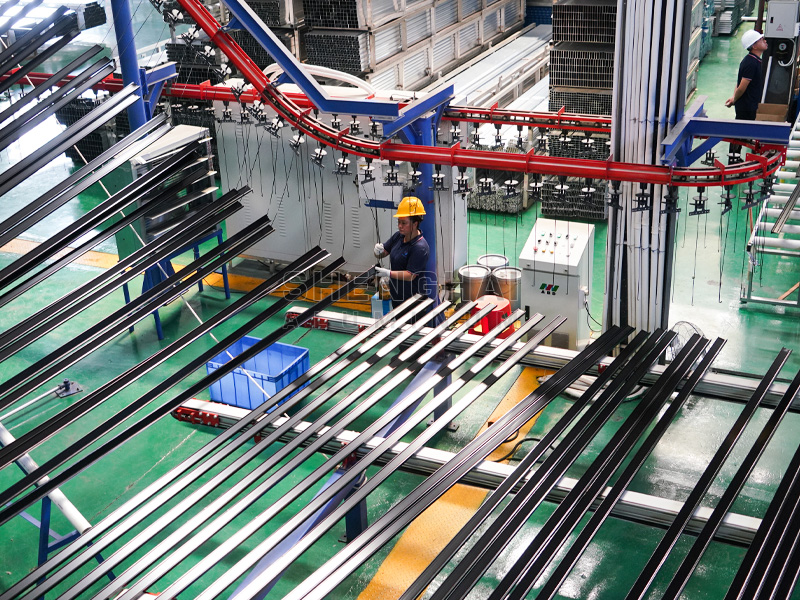

Powder Coated Aluminum Window Profile

During the manufacturing of aluminium window profiles, we use a key surface treatment method: powder coating. Crafted with a special process, a thick, protective powder coating is evenly sprayed onto the aluminum window frame. Compared with traditional paints, this coating not only offers stronger adhesion and better wear resistance, but also significantly enhances the durability, corrosion resistance, and structural strength of aluminum itself.At the same time, we offer a wide range of color options and support personalized color customization, enabling precise matches for architectural styles ranging from modern simplicity to classic elegance. This enables doors and windows not only to provide strong protection but also to add a refined aesthetic texture to the space.

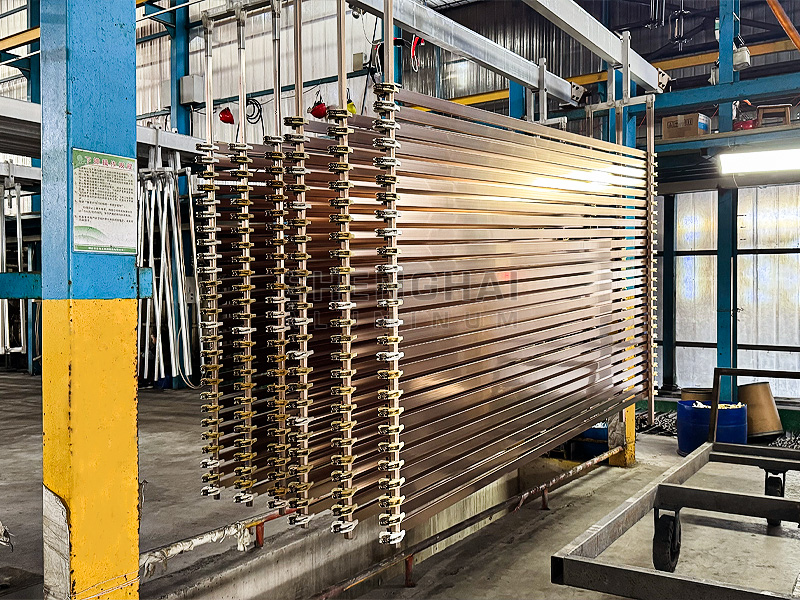

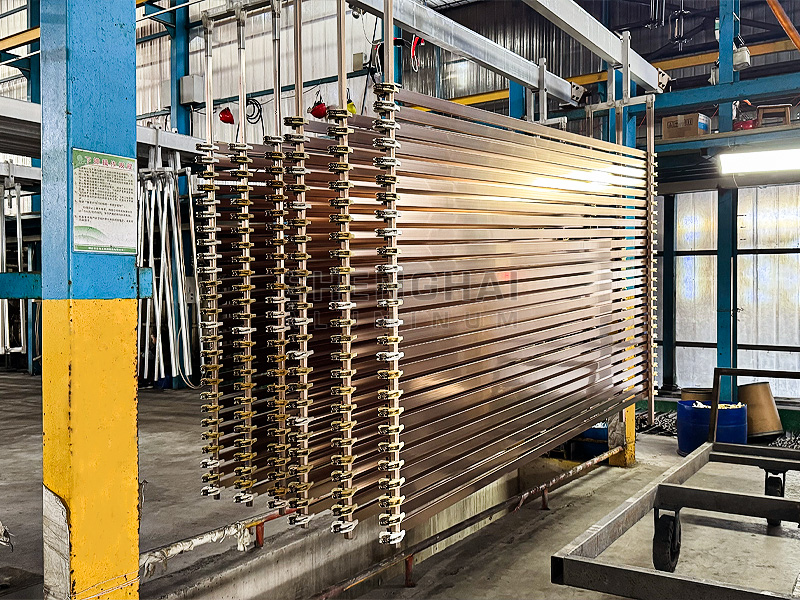

Anodized Aluminum Window Profile

In the production of aluminium window profiles, anodizing is a commonly used, extremely crucial surface treatment process. The aluminum surface is treated by electrochemical processes to form a dense, tough oxide film. This layer of oxide film not only significantly enhances the corrosion resistance and overall durability of aluminum Windows, but also effectively resists scratches and wear. It is especially suitable for extremely harsh environments such as beaches and deserts. Even when exposed to harsh conditions such as high-salt spray, intense UV radiation, and extreme temperature differences for a long time, it can still maintain its protective performance and is less prone to aging and rusting.Compared with powder coating, the color selection for anodizing is simpler (mainly in the original metallic color series), but it offers better durability and a delicate, high-end metallic luster, endowing aluminum Windows with a simple, elegant, modern texture. It can match various architectural styles without complex decoration. Daily maintenance requires only simple cleaning and minimal upkeep, keeping it smooth and bright for a long time.

At present, our European, North American, and Japanese customers, as well as those from South Korea, Australia, and other regions, all prefer anodized aluminum window extrusion, valuing its stable performance and long service life in harsh environments.

How To Choose the Color of Aluminum Window Profiles for Coastal Homes

The color selection for aluminum window extrusion profiles aligns with the building's overall design style, achieving a harmonious unity of aesthetic appearance and usage scenarios. We can offer you a variety of powder coating colors, including standard options like brown, red, white, and champagne. We also support custom colors to match your design plan, and can easily adapt to various decoration styles such as modern simplicity, light luxury retro, and natural simplicity. If the above standard color cards do not meet your personalized needs, we also offer full-color customization services. We can match powder coatings to any RAL color number to match the project's style. Whether it is a single-color full-body effect or a two-color clashing design, it can be precisely achieved.In addition, our powder coatings offer excellent durability and corrosion resistance and have been specifically optimized for coastal environments. Its surface texture is fine, and it will not fade even when exposed to strong ultraviolet rays and salty air for extended periods. Daily maintenance is extremely convenient - just dip a sponge in clean water and gently wipe it, and the window can maintain a clean and bright appearance for a long time. This ensures that your aluminium Windows not only remain aesthetically pleasing but also maintain reliable protective performance in harsh coastal climates.

Aluminum Profile Window VS uPVC Window

Aluminum alloy, as a metallic material, has extremely high strength in its profiles, excellent wind pressure resistance, and deformation resistance, making it highly suitable for use in coastal areas with strong winds and for open-window designs with large areas of glass. It is not prone to long-term deformation or warping. However, the hardness of uPVC material is relatively low. For large windows, thickened profiles are required, which can easily lead to sagging and deformation.After undergoing powder coating or anodizing, the corrosion resistance and UV resistance of aluminum window frames have been significantly enhanced. Even in the high-salt coastal areas and the humid, muggy southern environments, they are not prone to rust, aging, or fading. However, uPVC is prone to brittleness, yellowing, and cracking when exposed to prolonged sunlight, and its service life will be significantly shortened.

Overall, aluminum window profiles are the most suitable for coastal homes. The corrosion resistance and wind pressure resistance of aluminum extruded profiles are unmatched by other materials. Shenghai Aluminum has extensive experience in the aluminum door and window extrusion industry, and our clients come from the Middle East, Africa, Australia, Canada, Mexico, and other countries. If you would like to learn more about aluminum door and window profile solutions, please feel free to contact us for professional solutions.