How To Process Aluminum Window Frame Profile

Updated: 2 Dec 2025

Aluminum profiles are the most important load-bearing components in door and window structures, directly affecting the sealing, durability, and quality of aluminum windows. To properly process aluminum window profiles, one must master surface treatment techniques and possess advanced deep-processing capabilities. The more advanced the processing technology, the greater the stability and durability of aluminum doors and windows.

We all know that aluminum door and window profiles are not finished after extrusion molding; they require multiple deep-processing steps. If you want a more comprehensive understanding of how aluminum window frame profiles are processed, this article will provide a detailed explanation.

Common surface treatment methods for aluminum window profiles include:

1.Anodizing: Forms a dense oxide film, making the surface more wear-resistant, corrosion-resistant, and oxidation-resistant, suitable for high-end home decoration, building curtain walls, and sunrooms.

2. Powder Coating: Offers a wide range of colors, is UV-resistant, does not fade, and does not peel, making it suitable for outdoor use.

3. Wood Grain Transfer Technology: Utilizing high-temperature vacuum transfer technology, this technology achieves a natural wood grain effect on the profiles, commonly used in high-end projects such as villas, guesthouses, and commercial shops.

4.Fluorocarbon Coating (PVDF): Weather resistance can reach over 20 years, specifically designed for high-rise buildings and areas with extreme weather conditions.

In addition to these, we can also offer various process combinations to meet your requirements, thereby enhancing the brand influence and market competitiveness of your aluminum door and window system.

1.CNC Machining:

Precision grooving, drilling, and chamfering ensure accurate hardware installation. Assembly errors can be controlled within ±0.2mm.

2.Thermal Break Processing:

PA66 thermal break strip installation process and polyurethane infusion insulation technology effectively improve window insulation performance and reduce energy consumption.

3.Customized Profile Structure Processing:

Customizable to project requirements: Wall thickness, structural cavities, reinforcing ribs, and waterproof drainage channels. Always prioritizing sealing, stability, and service life.

Our Processing Advantages:

* We possess automated CNC machining centers

* Advanced surface treatment equipment

* High-precision tooling and fixture positioning

* Standardized process flow

* A professional engineering team can assist customers in optimizing designs

* 100% manual and instrumental dual inspection before shipment

We use advanced extrusion, CNC machining, anodizing, and powder coating to produce high-precision aluminum window frame profiles.

2. How to process aluminum window profiles?

Production includes extrusion, surface treatment, precision cutting, drilling, slotting, thermal break assembly, and final inspection.

3. Can you customize aluminum window frame profiles?

Yes, we support customized shapes, thicknesses, colors, surface treatments, and hardware processing.

4. Do you provide surface treatment for aluminum window profiles?

Yes, anodizing, powder coating, PVDF, wood grain, electrophoresis, and customized finishes are available.

5. Can I get an aluminum window frame profile sample?

Yes, samples are available for testing before the bulk order.

6. How to send RFQ for aluminum window profile?

Please provide: drawings, size, alloy grade, surface treatment, quantity, usage environment, and customization requirements. The more details, the more accurate the quotation you will receive.

In general, professional processing capabilities are also crucial for choosing high-quality extruded aluminum window profiles. Shenghai Aluminum not only provides extrusion solutions but also has professional capabilities for aluminum profile processing. To learn more about aluminum window frame profiles, please contact us immediately to obtain our aluminum door and window profile catalog and solutions.

We all know that aluminum door and window profiles are not finished after extrusion molding; they require multiple deep-processing steps. If you want a more comprehensive understanding of how aluminum window frame profiles are processed, this article will provide a detailed explanation.

Surface Treatment Processes: Improving the Performance of Aluminum Window Frame Profiles

Surface treatment of aluminum profiles not only improves aesthetics but is also a crucial step in resisting corrosion and extending lifespan. Different regions have different requirements for surface treatment; for example, coastal areas prioritize corrosion resistance, desert areas prioritize weather resistance, and humid areas prioritize oxidation prevention. Our window and door profile customers are from all over the world, and the aluminum profiles we provide for them are all custom-treated. Some countries have high requirements for the corrosion resistance of profiles, usually using hard anodizing. Other countries require a wide range of colors, usually using powder coating. So what are the standard surface treatment methods for aluminum window and door profiles?Common surface treatment methods for aluminum window profiles include:

1.Anodizing: Forms a dense oxide film, making the surface more wear-resistant, corrosion-resistant, and oxidation-resistant, suitable for high-end home decoration, building curtain walls, and sunrooms.

2. Powder Coating: Offers a wide range of colors, is UV-resistant, does not fade, and does not peel, making it suitable for outdoor use.

3. Wood Grain Transfer Technology: Utilizing high-temperature vacuum transfer technology, this technology achieves a natural wood grain effect on the profiles, commonly used in high-end projects such as villas, guesthouses, and commercial shops.

4.Fluorocarbon Coating (PVDF): Weather resistance can reach over 20 years, specifically designed for high-rise buildings and areas with extreme weather conditions.

In addition to these, we can also offer various process combinations to meet your requirements, thereby enhancing the brand influence and market competitiveness of your aluminum door and window system.

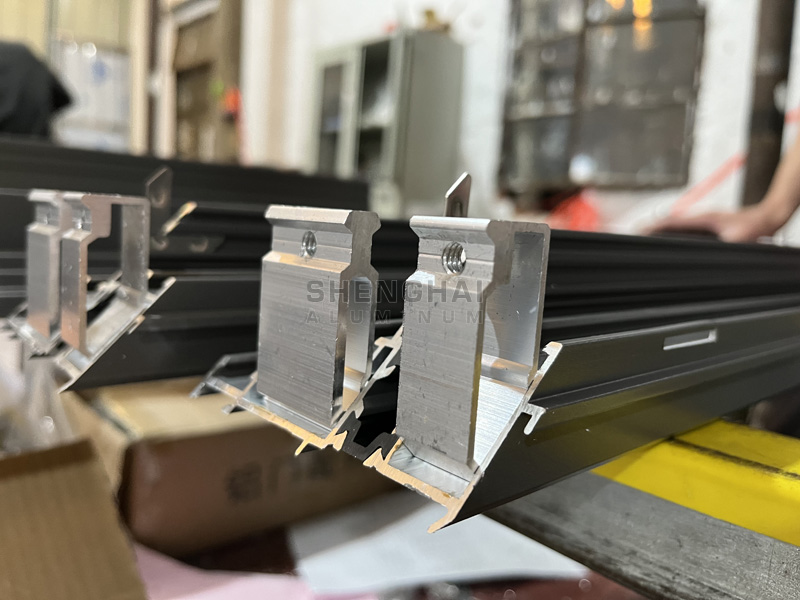

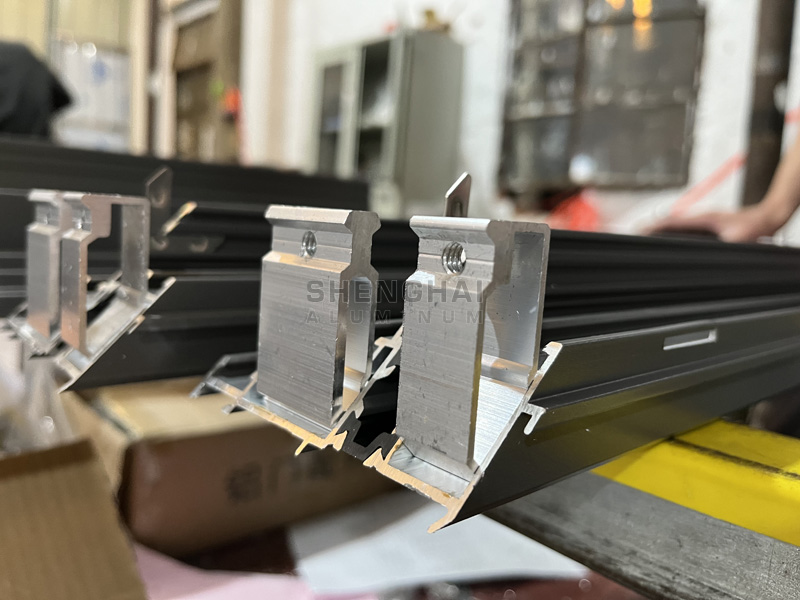

Precision Processing of Aluminum Window Frame Profiles

High-end aluminum window profiles undergo more than just simple post-extrusion processing; they involve a complete precision process:1.CNC Machining:

Precision grooving, drilling, and chamfering ensure accurate hardware installation. Assembly errors can be controlled within ±0.2mm.

2.Thermal Break Processing:

PA66 thermal break strip installation process and polyurethane infusion insulation technology effectively improve window insulation performance and reduce energy consumption.

3.Customized Profile Structure Processing:

Customizable to project requirements: Wall thickness, structural cavities, reinforcing ribs, and waterproof drainage channels. Always prioritizing sealing, stability, and service life.

Why Processing Capacity Determines Aluminum Window Quality

Processing capacity determines the quality of aluminum windows. Even using the same aluminum material, only through precision cutting, CNC machining, surface treatment, and deep processing can we ensure accurate profile dimensions, precise placement of hardware holes, and excellent sealing performance. This also improves weather resistance and lifespan. High-level processing technology directly affects the stability, durability, and overall quality of aluminum windows.Why Choose Us as Your Aluminum Door and Window Profile Supplier

We not only provide extruded profiles but also offer comprehensive door and window processing solutions, demonstrating our professionalism to our clients.Our Processing Advantages:

* We possess automated CNC machining centers

* Advanced surface treatment equipment

* High-precision tooling and fixture positioning

* Standardized process flow

* A professional engineering team can assist customers in optimizing designs

* 100% manual and instrumental dual inspection before shipment

FAQs about Aluminum Window Frame Profiles

1. How to make aluminum window frame profiles?We use advanced extrusion, CNC machining, anodizing, and powder coating to produce high-precision aluminum window frame profiles.

2. How to process aluminum window profiles?

Production includes extrusion, surface treatment, precision cutting, drilling, slotting, thermal break assembly, and final inspection.

3. Can you customize aluminum window frame profiles?

Yes, we support customized shapes, thicknesses, colors, surface treatments, and hardware processing.

4. Do you provide surface treatment for aluminum window profiles?

Yes, anodizing, powder coating, PVDF, wood grain, electrophoresis, and customized finishes are available.

5. Can I get an aluminum window frame profile sample?

Yes, samples are available for testing before the bulk order.

6. How to send RFQ for aluminum window profile?

Please provide: drawings, size, alloy grade, surface treatment, quantity, usage environment, and customization requirements. The more details, the more accurate the quotation you will receive.

In general, professional processing capabilities are also crucial for choosing high-quality extruded aluminum window profiles. Shenghai Aluminum not only provides extrusion solutions but also has professional capabilities for aluminum profile processing. To learn more about aluminum window frame profiles, please contact us immediately to obtain our aluminum door and window profile catalog and solutions.