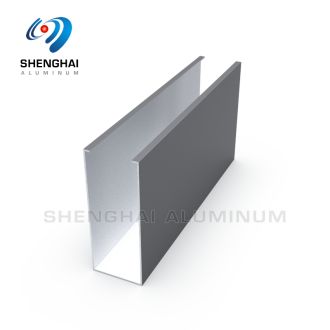

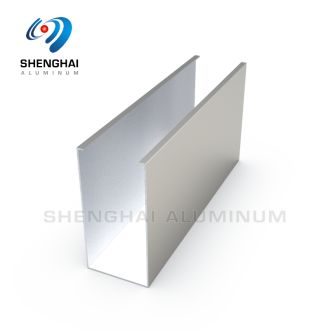

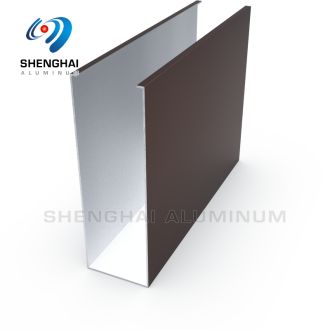

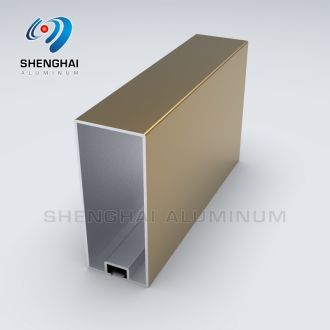

Aluminium U Baffle Ceiling Profiles

Model Number:

6061 6063 T5 T6

Color:

Sliver Anodizing or Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

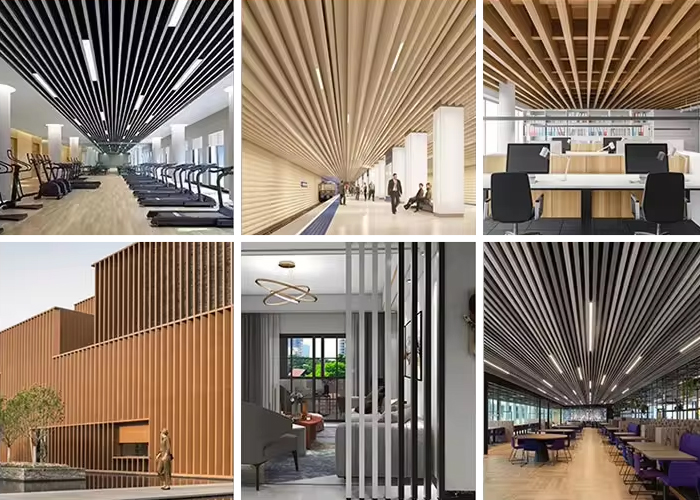

Aluminum profiles are an important material for suspended ceilings. Due to the advantages of aluminum profiles, suspended ceilings are becoming more and more popular in the decoration industry. The U-shaped ceiling profile we designed is a visible curtain-type ceiling. The surface treatment adopts wood grain/ powder coating, and the color is soft, which aligns with the current architectural decoration style. The U-shaped design can hide the building's pipes and other facilities without affecting equipment and air conditioning system installation.

There are many choices for aluminum ceiling baffles, including U-shaped, curved, special-shaped, etc. These are all popular decorative products now, and perforated aluminum ceiling baffles are also unique. Perforated aluminum ceiling baffles have good sound absorption properties when used with other accessories. It is suitable for public places like cinemas, shopping malls and other spaces. If you want to know more about ceiling profiles, please get in touch with us.

Specifications

Product: aluminum ceiling baffles

Bottom width: 20mm, 25mm, 50mm

Height: 50mm, 100mm, 150mm

Thickness: 1.0-2.0mm

Surface: powder coating, polyester paint, fluorocarbon paint, wood grain

Function: Fireproof, Moisture-Proof, Mould-proof, Smoke-proof, Sound-proof

Packing details: Packed in Standard export cartons with protective foam

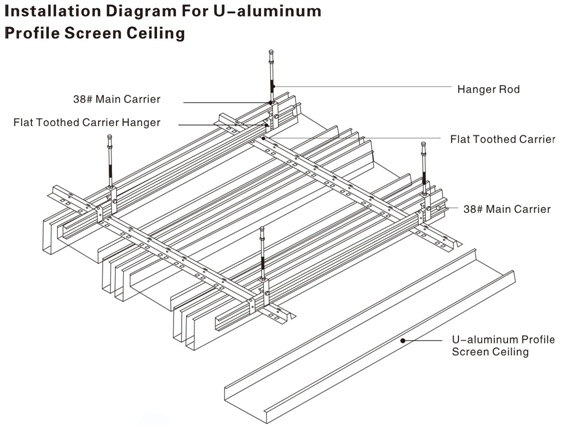

U shape aluminum baffle ceiling installationThere are many choices for aluminum ceiling baffles, including U-shaped, curved, special-shaped, etc. These are all popular decorative products now, and perforated aluminum ceiling baffles are also unique. Perforated aluminum ceiling baffles have good sound absorption properties when used with other accessories. It is suitable for public places like cinemas, shopping malls and other spaces. If you want to know more about ceiling profiles, please get in touch with us.

Specifications

Product: aluminum ceiling baffles

Bottom width: 20mm, 25mm, 50mm

Height: 50mm, 100mm, 150mm

Thickness: 1.0-2.0mm

Surface: powder coating, polyester paint, fluorocarbon paint, wood grain

Function: Fireproof, Moisture-Proof, Mould-proof, Smoke-proof, Sound-proof

Packing details: Packed in Standard export cartons with protective foam

Product Application

Aluminum Baffle ceiling strip application: Industrial and civil buildings, special buildings, interior partitions, suspended ceiling, wall, airport, bus station, museum, opera house, exhibition hall, shopping centre, conference hall, bar and etc.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Get a Quote