Solar & Industrial Aluminum Profiles for Middle East Projects

Color:

Sliver Anodizing or Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

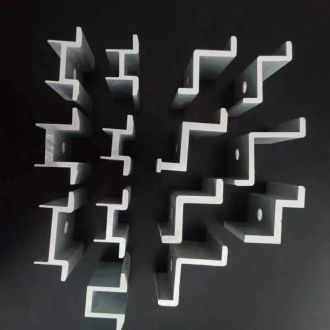

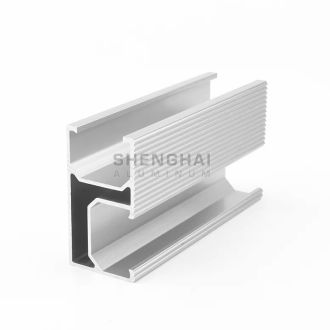

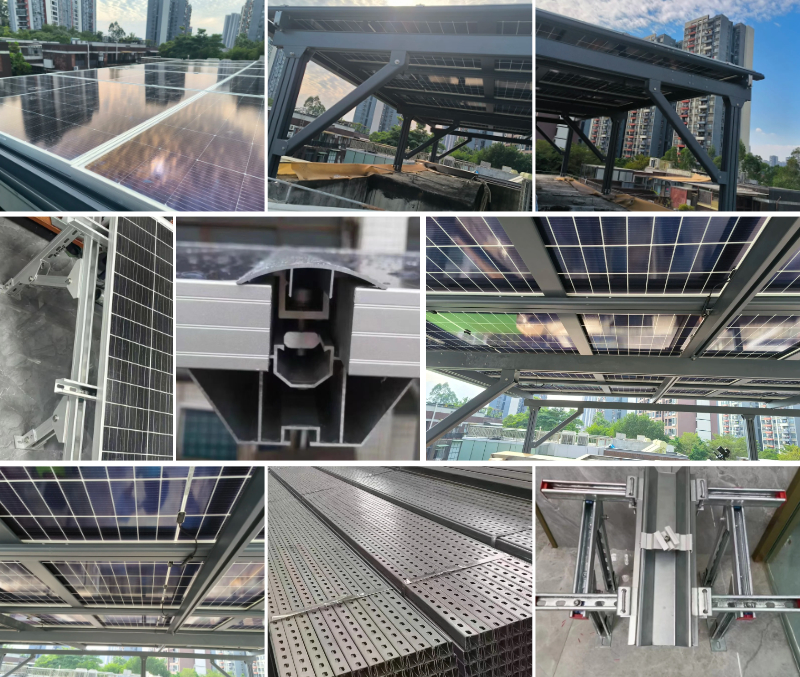

As the global energy structure transforms to clean and renewable energy, photovoltaic power generation systems are developing rapidly in high temperature and high radiation areas such as the Middle East, Africa and South Asia. As the bearing structure of photovoltaic modules, photovoltaic bracket systems have higher requirements for the corrosion resistance, strength and installation efficiency of profiles. The photovoltaic bracket aluminum profiles we provide are made of high-quality 6061-T6 and 6063-T5 aluminum alloys. After high-precision extrusion and surface oxidation treatment, they have high strength, salt spray resistance, UV resistance, sand and dust corrosion resistance and other characteristics, and can be used stably for more than 15 years under harsh climatic conditions. The products are widely used in rooftop solar brackets, ground-fixed photovoltaic structures, solar parking shed support systems, etc. to meet the diversified needs of photovoltaic projects.In addition to the photovoltaic industry, we also focus on providing various types of industrial aluminum alloy profile solutions, suitable for various types of automated factories, logistics equipment, assembly production lines, display rack structures, etc. We can customize T-slot aluminum profiles, aluminum alloy square tubes, equipment frame structure profiles, slide rail guide groove profiles and pipe connectors. The products have the advantages of light weight, modularization, high strength and easy assembly. With standardized connectors and bolt interfaces, it can be installed and used immediately, greatly saving man-hours and improving project flexibility, which is very popular among industrial automation and intelligent equipment integrators.

We support customization and OEM/ODM, and can provide a variety of cross-sectional structures, strength grades and color treatments (anodizing, spraying, electrophoresis, etc.) according to the standards of different countries/regions to ensure the product's beautiful appearance, corrosion resistance and durability. As a powerful supplier focusing on industrial aluminum profiles and photovoltaic bracket aluminum extrusion products, we are committed to providing customers with cost-effective aluminum profile solutions that can be delivered in a long term and adapt to various complex installation scenarios. Choose us, and choose a global, professional and standardized aluminum supporting partner.

Product Usage Scenarios:

Our customers from all over the world

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message